Practical Biology

A collection of experiments that demonstrate biological concepts and processes.

Observing earthworm locomotion

Practical Work for Learning

Published experiments

Investigating enzymes used in laundry detergents, class practical.

Laundry detergents are a familiar application of enzyme technology in our daily lives. Detergent manufacturers have robust protocols for assessing the added cleaning value of different enzymes, with different stains, different fabrics, different temperatures.

While you cannot replicate all these tests in your classroom, groups of students could each carry out a simple investigation of one factor, while controlling other variables.

Lesson organisation

This will depend on how open-ended you allow the planning and execution of an investigation to be.

Introducing the idea that enzymes are added to laundry detergent to improve cleaning performance could be brief, or take longer if you want to introduce more ideas about enzyme action, types of fabrics, the nature of stains, and the effects of reducing laundry temperatures. If you encourage each group of students to investigate one factor and allow time for sharing reports of the practicals at the end, you could cover several aspects of the technological application of enzymes to laundry.

It might be interesting to share the reports by posting them to a website and then asking each student to review another group’s report.

Apparatus and Chemicals

For each group of students:.

Access to a range of

- staining substances

- detergents – with and without enzymes ( Note 2 )

- water (including hot water)

Stirring rods

Thermometers

For the class – set up by technician/teacher:

Non-bio detergent at a suitable dilution ( Note 1 )

Enzyme preparations to add to the detergent ( Note 2 )

Range of fabrics: cotton, linen, nylon, rayon, silk, wool ( Note 3 )

Staining substances ( Note 4 )

Health & Safety and Technical notes

Refer to safety notes provided with your supplied enzyme preparation. Handling concentrated enzyme preparations is more hazardous than handling diluted enzyme preparations. Dry enzyme powder is hazardous if inhaled, so spills should be cleared up with a damp cloth before they dry out. Technicians should wear eye protection. They should avoid raising enzyme dusts in the air when preparing solutions, and should rinse splashes off the skin quickly and thoroughly.

Students should take similar care with dilutions of enzyme in detergent solutions, but the hazard is much reduced. Wash any detergent splashes from the eyes with copious running water or an eye wash bottle.

Read our standard health & safety guidance

1 A suitable dilution of detergent is around 5%, that is 5 cm 3 of detergent per 100 cm 3 . This is calculated from the typical detergent pack suggestion of 100 cm 3 of detergent in a medium soil wash and machines using around 20 litres of water for the wash cycle.

2 Provide portions of enzymes to add to known volumes of the detergent, or make up solutions of enzymes (protease only, lipase only, amylase only) in non-bio detergent. Students mix these to make enzyme cocktails, following their investigation plans.

NCBE supplies five detergent enzymes individually or in a pack of five. They supply lipase (Lipex™) in 100 cm 3 bottles. The data sheets in the packs recommend suitable amounts of enzyme to use as a starting point for any investigation. They also provide information about the enzyme including likely optimum temperature for enzyme action. NCBE recommend testing any protocol with different concentrations of enzyme before use with students, because enzyme activity in different situations and after storage is hard to predict. Use the data sheet provided with the enzyme to guide your decisions.

3 Web research into the source and nature of the fibres in different fabrics will reveal that some are plant products (varieties of cellulose fibres), some are synthetic polymers, and others are of animal origin (protein fibres). With their knowledge of enzymes, students should be able to work out which laundry enzymes are likely to have a negative effect on silk and wool.

4 Students may devise their own stains, but could include cooking oils, fresh grass, milk, egg yolk, chocolate sauce, rich gravy, fruit juice. Encourage students to be sparing in how they stain the fabric, especially if investigating fatty stains at low temperatures.

Ethical issues

There are no ethical issues with the practical procedure. You may need to avoid handling animal products to produce stains if you have strict vegetarians or vegans in the class.

SAFETY: Rinse any splashes of enzyme solutions from the skin quickly and thoroughly. Wear eye protection when handling enzyme solutions. Clean up spills with a damp cloth before they dry. Avoid raising dust into the air with detergents and powdered enzymes. Avoid rubbing eyes after handling solutions, washed fabrics etc.

Preparation

a Make up detergent and enzyme solutions ( Notes 1 and 2 )

b Prepare fabrics to test ( Note 3 )

Investigation

c You could provide a detailed protocol for an investigation for your students, or make investigation planning part of the activity. Fabrics will need to be stained, mixed with detergent and/or enzyme solutions at a certain temperature for a certain time, agitated in some way, rinsed and left to dry before assessing the stain-removing effects of the detergent/ enzyme mixes.

Teaching notes

The use of enzymes is often preferable to traditional chemical treatment. Traditional chemical treatments are often non-specific, not always easily controlled, and may require harsh conditions. Often they produce undesirable side effects and/or waste disposal problems. Enzyme-controlled reactions often give higher product quality, lower manufacturing cost, less waste and reduced energy consumption. The technical effects of enzymes can be controlled by changing enzyme dose, temperature, and reaction time. Because enzymes are catalysts, the amount added to accomplish a reaction is relatively small. For example, an enzyme preparation in most food uses is equal to 0.1% (or less) of the product.

Enzymes used in food processing are generally destroyed during subsequent processing steps and not present in the final food product. When enzymes are used to remove stains from fabrics, clothes can be washed at lower temperatures, thus saving energy. Enzymes provide an alternative to chlorine bleach for removing some stains from cloth. Using enzymes means the level of surfactants can be reduced, and permits the cleaning of clothes in the absence of phosphates. Enzymes also contribute to safer working conditions when they allow elimination of harsh chemical treatments during production processes. (Source: Enzyme Technical Association .)

A disadvantage of using enzymes in laundry detergent is that some people experience allergic or other reactions to traces of detergent on laundered clothing. Another is that protease enzymes will damage protein fibres in fabrics such as silk and wool.

Health & Safety checked, September 2010

www.ncbe.reading.ac.uk NCBE at Reading is a source for laundry detergent enzymes, and for many tried and tested protocols using enzymes. NCBE also provide a wide range of other biotechnology practical equipment, consumables and protocols.

(Websites accessed October 2011)

NOTIFICATIONS

Enzymes in washing powders.

- + Create new collection

Television commercials for washing powder often promote the "boosting power" of enzymes. Why are enzymes added to washing powder, and how do they work? Carry out some simple experiments to investigate this further.

What are enzymes?

Enzymes are biological molecules that catalyse (speed up) chemical reactions. Enzymes are specific—they will only work on particular molecules. For example, the enzyme sucrase will only bind with and break bonds in sucrose, not any other type of sugar.

Another characteristic of enzymes is that they can be re-used over and over again. A single enzyme will typically catalyse around 10,000 chemical reactions per second. This means that only a tiny amount of enzyme is needed to have a huge effect on a reaction.

The rate of enzyme activity depends on the amount of enzyme present, and also the temperature and pH of the reaction solution. The most favourable pH for many enzymes is 6-8, around neutral, but there are exceptions: pepsin, a digestive enzyme in the stomach, works best at pH 2.

The article Catalysing chemical reactions with enzymes includes an animated video outlining in detail how enzymes work.

People have been experimenting with ways to use the power of enzymes to clean clothing for a long time; in fact, the first patent was in 1913.

Because stains are made of different types of molecules, a range of enzymes are needed to break them down. Proteases break down proteins, so are good for blood, egg, gravy, and other protein stains. Amylases break down starches, and lipases break down fats and grease. Washing powders usually only contain one type of enzyme, though some have two or all three.

Experiments to test the functionality of enzymes

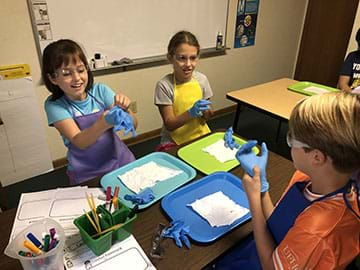

Activities can be carried out in the classroom to demonstrate the power of enzymes as cleaning agents.

- Investigating enzymes used in laundry detergents :Students plan an investigation on the performance of enzymes in laundry detergent, using a variety of fabrics and food stains.

- Breaking stains : This experiment requires a spectrophotometer and casein protein coloured with blue dye. The aim is to compare the effectiveness of ordinary detergent (usually made specifically to get rid of oils) with a protease solution (to target the protein part of a stain). Students can plot a graph of colour intensity against time as a measure of the stain removal. A series of questions could be incorporated into a student worksheet.

- A beginner's guide to enzymes in detergents . This is from the Novozymes' website site and provides some background information about the use of enzymes in detergents.

Sources of enzymes

Purchasing enzymes The National Centre for Biotechnology Education at the University of Reading in the UK supplies a range of different digestive enzymes that can be used for experiments. The enzymes they use are: savinase and alcalase (both proteases), termamyl (amylase), lipolase (lipase), and celluzyme (cellulase).

Natural sources You can get protease activity from natural products like kiwifruit and pineapple. We suggest that you crush the fruits in a buffer and then strain them to remove the fruit pulp. The filtered solution will contain a range of cellular molecules, including some proteases. This is covered further in the article Fruit enzyme uses .

- Try a simple experiment to look at the action of marinades . It could be used as an introduction to experiments with enzymatic digestion of proteins and/or as the basis for further experimentation .

Another natural source of digestive enzymes is the pancreas, which can be collected from an abattoir and blended with buffer.

A note about enzyme units

The activity of enzymes is given as U/g (Units per gram), where the unit relates to a specific assay (measure of enzyme activity), e.g. one unit will liberate 1 mg of substrate per minute at pH7.0 at 25ºC.

Any enzyme solutions that are bought will have different levels of activity, and this should be taken account in a comparative experiment (i.e. make sure that the number of ‘units’ are comparable when testing different enzymes for their effectiveness).

The more crude the extract is, the lower the U/g measure.

See our Enzymes Pinterest board for more resource ideas.

Additional activity ideas

You also might like to try these activity ideas:

- Cleaning time using the power of enzymes experiment, (including video) from the STEAM Transcultural Science Communication Summer School website.

- The Power of Enzymes! from TeachEngineering help students learn about the role of enzymes in digestion and why enzymes are used in laundry detergents.

See our newsletters here .

Would you like to take a short survey?

This survey will open in a new tab and you can fill it out after your visit to the site.

- Summer School

- Experiments

- Reset Search

- communication

- Computer Science

- Creative Art Projects

- Creative Arts Projects

- Engineering & Technology

- environment

- lesson plan

- Maths & Stats

- Photography

- Science Communication

Level of Education

Post Secondary

Recommended Age

Time Required

- ~10 minutes

- ~20 minutes

- ~30 minutes

- ~45 minutes

1 day or more

Number of people

- 100 – 200 €

Supervision

Cleaning time using the power of enzymes

Meta Description

Learning Objectives

This experiment will show you how biological washing powders work to remove all those nasty stains. The experiment will also guide you to understand how differences in temperature affect stain removal, so that next time you make a mess on your clothes, you can clean it yourself.

Enzyme Biological catalysts.

Increase reaction rate by providing an alternative route having lower activation energy.

Change in structure.

The molecule acted upon by the enzyme.

Hydro means water while lysis means to break. Therefore hydrolysis refers to the breaking of a chemical bond by introducing a water molecule.

Tertiary structure

The 3D shape of a polypeptide.

Active site

The part of the enzyme to which the substrate attaches and undergoes a chemical change.

Polypeptide Amino acid chain.

Step 1 Dissolve around 0.6 g of the biological powder in around 600 mL of water. If it does not dissolve, heat the water gently until the powder dissolves.

Stain a piece of cloth with 10 drops of orange juice. The drops should be placed in the same spot, using a pipette.

Place the cloth in a beaker containing 100 mL of the dissolved biological powder.

Repeat this for the chocolate sauce and cooking oil.

Repeat steps 2-4 but this time heating the beakers containing the stained cloths at around 37 degrees on a hot plate or bunsen burner for 30 minutes (using the thermometer to check).

Leave the cloths in the beakers for around 24 hours.

Remove the cloths and observe the differences in stain removal between room temperature and an increased temperature.

If you want to carry out the experiment at home and you do not have access to a bunsen burner or hot plate, you can prepare a water bath instead. This can be done by pouring water in a pan and then placing the beaker inside the pan. Add hot water in between the pan and the beaker until the temperature inside the beaker is around 37 degrees. Add hot/cold water as necessary to the pan.

Instead of using the suggested staining materials, you might want to utilise other staining agents such as soil (which can produce quite a mess) or other fruit juices.

In science, you have to make do with what you have available. Hence, if you do not have beakers, practice this concept, and utilise other items instead such as baby food jars, jam jars, mugs.

Biological washing powder may cause serious eye irritation therefore it is important to wash your hands after the experiment. You might also want to reduce any risks and wear gloves. http://www.bunzlchs.com/medias/sys_master/root/h23/h22/8815643951134/032065.pdf

Since the staining materials can be rather messy, it would be of good practice to wear a lab coat during the experiment.

In case of any allergies to the staining, materials suggested, you can always use other food items instead such as soya sauce or ketchup.

Imagine you are a football player and following an important match your gear is a total mess. You have grass stains on the shirts, on the shirts and on the socks. You have another game in two days so you need to clean your gear ASAP so you immediately place it in the washing machine. And that is what we are going to practice in this experiment. The science of how your gear gets clean every time you place it in a washing machine using biological washing powder.

What is biological washing powder? A washing powder that contains enzymes.

What are enzymes? Biological catalysts.

What will happen to the stain once the temperature is increased? The rate of reaction increases resulting in greater stain removal.

What happens if you increase the temperature too much? Enzymes denature, no longer functional in removing stains.

What is the difference between biological washing powders and non-biological washing powders? Biological washing powders contain enzymes.

Biological washing powders use enzymes to remove stains. Enzymes are molecules that help speed up reactions. They do so by finding an alternative reaction route which has a lower minimum energy required for a reaction to occur.

Stains are made of a variety of different molecules and since enzymes are specific, a range of enzymes are needed in order to remove the stains. Specificity means that the enzyme can only act on a specific type of substance. This is very important so that enzymes only work on specific chemical reactions and not other reactions which they were not meant to work on. http://www.ducksters.com/science/biology/enzymes.php

To break up those greasy stains, lipase enzymes are required. These enzymes break down the fats to simpler compounds. To break up stains that are made of proteins for example blood and gravy, protease enzymes are used. These enzymes break up the proteins into peptides (2 or more peptides stick to each other to form a protein), or amino acids (the building blocks of peptides) which are even smaller than peptides. The products produced after the substrate were acted upon by the enzymes are soluble and hence can easily be washed out with water, thus removing the stain. https://www.sciencelearn.org.nz/resources/1947-enzymes-in-washing-powders http://www.bbc.co.uk/schools/gcsebitesize/science/triple_ocr_gateway/beyond_the_microscope/enzymes_in_action/revision/2/

The stains on the cloth which were exposed to a temperature of 37 degrees, faded the most. This is as when the temperature rises, the molecules making up the stains (referred to as substrates)and the enzymes present in the biological washing liquid have more energy. The increase in energy increases the chances for the substrate and enzymes to meet and react. This in turn increases the rate of reaction between the substrate and the enzymes leading to a fainter stain. http://www.rsc.org/Education/Teachers/Resources/cfb/enzymes.htm

A high temperature would cause the enzyme to lose its shape. On doing so, the enzyme would no longer fit to the substrate and hence loses its functionality. Therefore, it would no longer function in removing the stain.

Those stains which were not acted upon by the enzymes, and thus remain unchanged, could be due to the fact that there was no enzyme specific to that substrate making up the stain.

Biological washing powders use enzymes to help remove stains. Enzymes are globular proteins that act as biological catalysts. They help speed up reactions by providing an alternative reaction route which has lower activation energy. Due to a specific tertiary structure, enzymes are specific, that can only work against one type of substrate molecule. This is achieved through a specific active site. The substrates are exactly complementary to the active site, hence any change in the active site would not allow the substrates to fit into this site, and would thus not be acted upon. http://www.chemguide.co.uk/organicprops/aminoacids/enzymes.html

The process occurring can be summarized as follows:

Enzyme+Substrate ⇋ Enzyme-Substrate complex → Enzyme + Product.

The enzymes present in biological washing powders include proteases that cleave proteins (present for example in bloodstains) through a hydrolysis reaction (addition of a water molecule in the peptide bond) into smaller polypeptide chains. https://www.ncbi.nlm.nih.gov/books/NBK22526/ Lipases are also present. These enzymes breakdown fatty molecules such as those found in grease stains into fatty acids and glycerol molecules. http://www.bbc.co.uk/schools/gcsebitesize/science/triple_ocr_gateway/beyond_the_microscope/enzymes_in_action/revision/2/

In this experiment, the enzyme activity at different temperatures was tested. It was noted, that an increase in temperature caused the formation of a fainter stain. This is as upon increasing the temperature, the substrates (which make up the stains), and the enzymes have an increase in energy. Hence, an increase in temperature results in a greater chance for the substrates and enzymes to collide with an energy equal (or greater than) the activation energy required for the reaction to occur. http://www.chemguide.co.uk/organicprops/aminoacids/enzymes2.html#top

Apart from this, an increase in temperature results in a greater chance for a successful collision between the substrates and the enzymes. This is as an increase in energy leads to an increase in motion for both the substrate and enzymes and hence has a greater chance of colliding. http://www.chemguide.co.uk/organicprops/aminoacids/enzymes2.html#top

An increase in reaction rate with an increase in temperature occurs until the enzyme becomes denatured at which point the substrate is no longer exactly complementary to the enzyme due to a change in the enzyme’s tertiary structure. This makes the enzyme no longer functional.

Applications

The biological washing powders are used to enhance the breakdown of fats and proteins present on our dirty clothes. Since they can function in relatively low temperatures, they can also save us energy! http://www.rsc.org/images/TM0313%20Trade%20secrets%20-%20bio%20or%20non-bio%20washing%20powder_tcm18-230874.pdf

Apart from acting as washing powders, enzymes have a variety of other applications including for medicinal purposes. Common enzymes used in the medical field include asparaginase which is a therapeutic enzyme used against leukaemia, collagenase used against skin ulcers and urokinase used to treat blood clots. http://www1.lsbu.ac.uk/water/enztech/medical.html

Research conducted in Italy in the year 2016 proposed a set up of a business plan for the development and selling of products including enzyme formulations for biosensing and decontamination/detoxification. These would be used on surfaces such as air, water, and skin. http://cordis.europa.eu/project/rcn/198535_en.html

In the same year, an article published by the Cold Spring Harbor Laboratory Press showed key insights in the role of TET enzymes in DNA methylation, development and cancer. Abnormalities in DNA methylation are often observed in diseases. The TET enzymes in turn show a locus-specific reversal of DNA methylation and this article highlights the recent advances in understanding the role of these TET enzymes. http://genesdev.cshlp.org/content/30/7/733.short

A change in pH is known to cause a change in enzymatic activity. Show this by adding another variable to the experiment which is pH. This can be done by adding lemon juice to the biological washing powder to increase acidity. The observed results are compared with biological washing liquid in basic environment which can be done by adding household ammonia to the biological washing liquid.

Enzymes can be denatured. Show at what temperatures the enzymes experience this phenomenon by testing the experiment in a wide range of temperatures and observe at which temperatures the stain remains the same even though it was carried out an elevated temperature.

Test what enzymes are present by using different stains. This can be done by using protein stains to show if protease enzymes are present, fatty stains to show if lipases are present and starch stains to show if amylase enzymes are present.

Preparation: 20mins

Conducting: 1 day

Clean Up: 15 mins

Number of People

4 participants

Biological washing powder Fabrics 6 Beaker Thermometers Water Cooking oil Orange juice Chocolate sauce Bunsen burner (or hot plate)

Contributors

Chemistry for Biologists

Biology for KidsEnzymes

The Difference Between Bio and Non-Bio Detergent

The use of enzymes in detergents

Using enzymes

Biological Detergents | Organic Chemistry | Chemistry | FuseSchool

Enzymes (Updated)

How Enzymes Denature | Cells | Biology | FuseSchool

Additional Content

What are enzymes? (Beginner)

The Difference Between Bio and Non-Bio Detergent (Intermediate)

Enzymes for Cancer Low Enzymes Levels Found With Cancer (Advanced)

Cite this Experiment

Aquilina, M. C., & Styles, C. (2020, June 26). Cleaning time using the power of enzymes. Retrieved from http://steamexperiments.com/experiment/cleaning-time-using-the-power-of-enzymes/

First published: June 26, 2020 Last modified: July 28, 2020

Leave a Reply Cancel Reply

You must be logged in to post a comment.

Lesson The Power of Enzymes!

Grade Level: 5 (4-6)

Time Required: 45 minutes

Lesson Dependency: None

Subject Areas: Biology, Chemistry, Life Science, Measurement, Physical Science

- Print lesson and its associated curriculum

Activities Associated with this Lesson Units serve as guides to a particular content or subject area. Nested under units are lessons (in purple) and hands-on activities (in blue). Note that not all lessons and activities will exist under a unit, and instead may exist as "standalone" curriculum.

- Clean, Green Washing Machine Challenge

| Lesson | Activity |

TE Newsletter

Engineering connection, learning objectives, worksheets and attachments, more curriculum like this, introduction/motivation, associated activities, lesson closure, vocabulary/definitions, user comments & tips.

Laundry is a real-world problem to which we can all relate. Engineers work to solve all types of problems, including how to create chemicals that help us in our daily lives. In the case of cleaning agents used in household products such as laundry detergent, chemical engineers use their knowledge of chemistry to engineer formulas. Engineers look to a variety of sources to solve problems and the human body is an excellent source of inspiration. For example, enzymes are present in the digestive system of the human body and these digestive enzymes—amylase, protease and lipase—have a specific function of breaking down food. Engineers use this scientific knowledge to create a laundry detergent using these enzymes which break down and remove a variety of different laundry stains created by foods.

After this lesson, students should be able to:

- Explain the role of enzymes in digestion.

- Explain why enzymes are used in laundry detergent.

Educational Standards Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards. All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN) , a project of D2L (www.achievementstandards.org). In the ASN, standards are hierarchically structured: first by source; e.g. , by state; within source by type; e.g. , science or mathematics; within type by subtype, then by grade, etc .

Ngss: next generation science standards - science.

View aligned curriculum

Do you agree with this alignment? Thanks for your feedback!

International Technology and Engineering Educators Association - Technology

State standards, florida - english.

Have you ever wondered how food gets digested in your body? Our body needs food for energy and to help our cells work. When we eat food, it travels through our digestive system. Along the way, the food gets broken down by special helpers called enzymes. Enzymes are proteins that help the body digest food. There are many kinds of enzymes in our body, but there are three main enzymes that help us break down most of the food we eat. The first one, called amylase , helps us break down carbohydrates like pasta or cereal. The second one, protease , helps us break down proteins like meat or cheese. The third enzyme lipase helps us break down fats like oils or butter.

Now we are going to read a book to help us better understand how the digestive system works. While we read this book, I want you to notice whenever the word 'enzymes' comes up in the book.

(Read the book: Amazing Body Systems: Digestive System , by Karen Latchana Kenney or A Journey Through the Digestive System with Max Axiom, Super Scientist , by Emily Sohn.)

Now let’s go back to the pages where enzymes were mentioned. Where were the enzymes in the body? How do they work in digestion? (Repeat for each occurrence.)

When you eat food, do you ever spill and make a stain on your clothes? (Prompt students to say yes or no to this question.) What do you do when you get a stain on your clothes? (Possible answers: someone in my family helps me wash it out, or I wash it out, etc.) . Some laundry detergents include enzymes in their active ingredients.

Based on what you now know from the reading and our discussion, why do you think laundry detergents would include enzymes in their ingredients? (Possible answers: enzymes work on stains, enzymes digest food stains, etc.) .

Lesson Background and Concepts for Teachers

Teachers need to know some background information on enzymes role in digestion and how enzymes are used in laundry detergents. Please use the books and links below for background information:

- A Journey Through the Digestive System with Max Axiom, Super Scientist, by Emily Sohn

- Amazing Body Systems: Digestive System, by Karen Latchana Kenney

- Video: What are the enzymes of the digestive system? https://www.youtube.com/watch?v=Ej-WkJEaXNU

- Video: Biological detergents, https://www.youtube.com/watch?v=23n4RNwptDg

- Video: Enzymes, https://www.youtube.com/watch?v=qgVFkRn8f10

- What are digestive enzymes? https://www.wisegeek.com/what-are-digestive-enzymes.htm

Watch this activity on YouTube

We can learn a lot from the human body. Today we learned that we can break down stains with the same enzymes that our bodies use to break down foods.

amylase: An enzyme that breaks down carbohydrates.

detergent: A substance that cleans.

digestion: The process of breaking down food by mechanical and enzymatic action to be used by the body.

enzyme: A protein that speeds up a chemical reaction.

lipase: An enzyme that breaks down fats (lipids).

protease: An enzyme that breaks down proteins.

Pre-Lesson Assessment:

| What we - Enzymes | What we - Enzymes | What we - Enzymes |

Lesson Summary Assessment:

| What we - Enzymes | What we - Enzymes | What we - Enzymes |

| is a protein that speeds up a chemical reaction. work in our digestive system is an enzyme that breaks down carbohydrates is an enzyme that breaks down proteins is an enzyme that breaks down fats (lipids). |

Exit Ticket: Have students complete the Exit Ticket .

Lesson Extension Activities

Using the Laundry Test Lab Worksheet , students can test 2 or 3 different enzymatic laundry detergents on some typical foods to test different stains to see which is the hardest to get out or easiest. Students can have fun squeezing the bottles on to clean rags to make the stains and then testing detergents to see which one is most effective at getting out the stains. Students could use beakers or graduated cylinders to measure the water and detergent and pipettes to transfer the water and detergent onto the stains. Students can use rulers to measure the size of the stain before and after using the detergent and water.

This lesson introduces students to the main parts of the digestive system and how they interact. In addition, students learn about some of the challenges astronauts face when eating in outer space. Engineers figure out how to deal with such challenges.

To reinforce students' understanding of the human digestion process, the functions of several stomach and small intestine fluids are analyzed, and the concept of simulation is introduced through a short, introductory demonstration of how these fluids work. Students learn what simulation means and ho...

Contributors

Supporting program, acknowledgements.

This curriculum was based upon work supported by the National Science Foundation under RET grant no. EEC 1711543— Engineering for Biology: Multidisciplinary Research Experiences for Teachers in Elementary Grades (MRET) through the College of Engineering at the University of Florida. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: October 26, 2020

- Animal health

- Animal nutrition

- Latest Insights Animal Health & Nutrition

- Product finder - Animal Health & Nutrition

- Trigo y cereals de invierno

- Fruit Crops

- Wheat & small grains

- Oil seed rape

- Agriculture & industry

- Wastewater & sewage sludge

- Latest insights - BioAg

- Product finder - BioAg

- Biomass conversion

- Fermentation

- Fiber conversion

- Liquefaction

- Saccharification

- Latest Insights - Bioenergy

- Product finder - Bioenergy

- Carbohydrases

- Oxidoreductases

- What is biocatalysis?

- Cell culture

- Diagnostics

- Latest Insights - Fine Chemicals

- Product finder - Fine Chemicals

- Feather protein hydrolysates

- Fish protein hydrolysates

- Gelatin & hydrolized collagen

- Glycosaminoglycans (GAGs)

- Meat protein hydrolysates

- Other protein sources

- Acrylamide reduction

- Appealing appearance

- Dough conditioning

- Dough strengthening

- Flour correction

- Gluten strengthening

- Health & Nutrition

- Reduce Acrylamide - Baked Goods

- Reduce Acrylamide - Breakfast Cereals

- Attenuation control

- Cereal cooking

- Craft brewing

- Diacetyl control

- Fermentation control

- Raw material optimization

- Separation & filtration

- Dairy protein

- Process Enhancement

- Viscosity reduction

- Corn wet milling

- Isomerization

- Specialties

- Wheat separation

- Apples & pears

- Berries & grapes

- Citrus fruits

- Clarification

- Tropical fruits

- Latest Insights Food & Beverages

- Enzymatic interesterification

- Oleochemicals

- Specialty fats

- Flavour enhancers

- Plant protein hydrolysates

- Plant-based dairy

- Plant-based meat

- Product finder - Food

- Automatic dishwash

- Hand dishwash

- Latest Insights - Household Care

- Complex laundry issues

- Fuzz and Pills

- Grease stains

- Pectin stains

- Protein stains

- Redeposition

- Starch stains

- Microbial cleaning

- Odor control

- Product finder - Household Care

- Humanhealth Human Health

- Latest Insights - Leather & textiles

- Acid bating

- Area expansion

- Unhairing & liming

- Product finder - Leather & Textiles

- Biopolishing

- Biopreparation

- Bleach clean up

- Denim abrasion and finishing

- Cleaning in place

- Drain openers

- Hard surface cleaning

- Latest Insights - Professional Cleaning

- Medical cleaning

- Product finder - Professional Cleaning

- Professional laundry

- Septic tank cleaning

- Warewashing

- Bleach boosting

- Deposit control

- Fiber modification

- Latest Insights Pulp & Paper

- Product finder - Pulp & paper

- Starch modification

- Ammonia Removal

- COD Removal

- FOG Removal

- Hydrocarbon & phenol removal

- Latest Insights Water & waste

- Product finder Water & Waste

- Lagoon treatment

- Sludge dewatering

- Sludge digestion

- Advancedproteinsolution Advanced Protein Solutions

- Recirculating aquaculture systems

- Warm water aquaculture

- Household Care

- A beginner’s guide to enzymes in detergents

- Animalhealthandnutrition Animal Health & Nutrition

- Bioag BioAg

- Bioenergy Bioenergy

- 04 3 Fine Chemicals

- Foodandbeverages 0 Food & Beverages

- Householdcare Household Care

- 08 2 0 Leather & textiles

- Professionalcleaning Professional Cleaning

- Pulpandpaper Pulp & paper

- Waterandwaste Water & Waste

A beginner's guide to enzymes in detergents

Enzymes are increasingly important to detergent formulators for a wide range of tasks, including laundry, automatic dishwashing, and cleaning of industrial equipment used in the food industry. key trends in the market are driving their usage, but there are some considerations for producers using enzymes in detergents..

By Peter Dybdahl Hede , M.Sc. (Chem. Eng.), Ph.D. May 7, 2020

Although the detailed ingredient lists for detergents vary considerably across geographies and categories, the main detergency mechanisms are similar. Stains are removed by mechanical action assisted by enzymes, surfactants, polymers, and builders.

Surfactants of various kinds help wash liquor to wet fabrics, and they assist in removing various stains by lowering the surface tension at the interface between the wash liquor and the fabric. Anionic surfactants and polymers further increase the repulsive force between the original soil, the enzymatically degraded soil, and the fabric, which prevents the soil from redepositing on the fabric.

Builders act to chelate, precipitate calcium and magnesium components, to provide alkalinity and buffering capacity, and to inhibit corrosion. Enzymes in (heavy-duty) detergents degrade and thereby help solubilize substrate soils attached to fabrics or hard surfaces (e.g., dishes). Cellulases clean indirectly by gently hydrolyzing certain glycosidic bonds in cotton fibers. In this way, particulate soils attached to microfibrils are removed. A further desirable effect of cellulases is to impart greater softness and improved color brightness of worn cotton surfaces.

By helping to remove fuzz and pills on cotton fabrics, cellulases keep them looking new.

Many detergent brands are based on a blend of two or more enzymes - sometimes as much as eight different enzymes. One of the driving forces behind the development of new enzymes and the modification of existing ones for detergents is to make enzymes more tolerant of other ingredients, such as builders, surfactants, and bleaching chemicals, as well as of alkaline. The trend toward lower wash temperatures, in particular in Europe, has also increased the need for additional and more efficient enzymes. Starch and fat stains are relatively easy to remove in hot water, but the additional cleaning power provided by enzymes is required in cooler water.

Most widely used enzymes

The most widely used detergent enzymes are hydrolases, which remove protein, lipid, and polysaccharide soils. Research is currently being carried out with a view to extending the types of enzymes used in detergents. Many complex, stubborn stains come from a range of modern food products such as chocolate ice cream, baby food, desserts, dressings, and sauces. To help remove these stains as well as classic stains such as blood, grass, egg, and animal and vegetable fat, a number of different hydrolases are added to detergents.

The major classes are proteases, lipases, amylases, mannanases, cellulases, and pectinases. Historically, proteases were the first of these to be used extensively to increase the effectiveness of laundry detergents. Cellulases contribute to cleaning and overall fabric care by maintaining, or even rejuvenating, the appearance of washed cotton-based garments through selective reactions not previously available when washing clothes with surfactants unamended with enzymes.

Some lipases can act as alternatives to current surfactant technology by targeting greasy lipid-based stains.

Recent investigations show that multi-enzyme systems may replace up to 25% of a laundry detergent’s surfactant system without compromising the cleaning effect. This leads to a more sustainable detergent that allows cleaning at a low wash temperature.

Mannanases and pectinases are used for hard-to-remove stains of salad dressing, ketchup, mayonnaise, ice cream, frozen desserts, milkshakes, body lotions, and toothpaste as well as banana, tangerines, tomatoes, and fruit-containing products such as marmalades, juices, drinkable yoghurts, and low-fat dairy products.

The obvious advantages of enzymes make them acceptable for meeting consumer demands. Due to their catalytic nature, they are ingredients requiring only a small space in the formulation of the overall product. This is of particular value at a time where detergent manufacturers are trying to make their products more compact.

Washing with laundry bars.

In many parts of the world, strongly colored and stubborn stains from blood, sebum, food soils, cocoa, and grass are removed with the help of laundry detergent bars.

Such stain removal and washing by hand are one of the more time-consuming and physically demanding domestic tasks which can be made easier with the use of enzymes. After decades of very little performance enhancement for laundry bars, a specially formulated protease that empowers the producer to create products that stand out from non-enzymatic laundry detergent bars is now available, offering effective and effortless washing.

With the protease product Easyzyme® in laundry bars, washing is shortened by at least one rinse and requires much less scrubbing. In addition to obtaining a superior result, laundry bars containing the enzyme may be formulated to be milder to the hands than old-type bars without enzymes.

Washing cold.

Most of the energy spent during a household machine wash is used to heat the water. Thus, the most efficient way to save energy and thereby reduce carbon dioxide emissions is to lower washing temperatures.

The wide spectrum of enzymes that are available today, combined with a choice of appropriate other ingredients such as surfactants and bleaching systems specifically selected to work at low temperatures, has enabled manufacturers to produce cold water detergents.

Enzymes in dishwashing

Modern dishwashing detergents face increasing consumer demands for efficient cleaning of tableware. Enzymes are key ingredients for effectively removing difficult and dried-on soils from dishes and leaving glassware shiny. Enzymes clean well under mild conditions and thereby assist to reduce clouding of glassware.

In addition, enzymes also enable environmentally friendly detergents. Phosphates have been used in the past in dishwashing detergents to get dishes clean, but they harm the aquatic environment and are increasingly being banned in detergents around the world. The combination of modifying detergent compositions and using multi-enzyme solutions enables detergent manufacturers to replace phosphates without compromising the cleaning performance. For removal of protein soils, proteases are used; and amylases are used to remove starch soils.

Proteases for cleaning dishes and cutlery .

Some of the more difficult soils on dishes and cutlery are blends of egg yolk/milk, egg yolk, whole egg, and egg white as well as minced meat and oatmeal. The reason for this is the content of protease inhibitors in these foods. The protease Blaze Evity® by Novozymes has been specifically engineered to overcome high levels of protease inhibitors from eggs. These inhibitors effectively inactivate detergent proteases, resulting in reduced cleaning performance not just on the egg stain itself, but on all protein-containing soils in the same dishwasher load.

Amylases for cleaning starch-containing soils from dishes.

In automatic dishwashing, most of the soil is physically washed off by the water jets. However, foods usually leave behind thin films of starch-/protein-containing soils. If they are not removed, these films will build up over time. Larger lumps of burnt-on and caked-on soils may also remain. These soils are the main target for enzymes.

Enzymes target thin films of starch-/protein-containing soils that can build up over time.

The history of enzymes in detergents

The first enzyme-containing detergent was introduced to the household market as early as 1913. Röhm & Haas in Germany added trypsin extracted from pig pancreas to their detergent Burnus, utilizing a patent of Dr. Otto Röhm.

As the protease trypsin had insufficient activity and poor stability in detergents, the enzyme concept did not catch on until 1963 when Novo launched a more alkali- and builder-stable bacterial protease called Alcalase®. Small detergent producers in Switzerland and the Netherlands were pioneers in the commercial use of Alcalase, which was initially considered useful only for washing blood-stained laundry from hospitals and slaughterhouses.

For almost 20 years, bacterial proteases from different suppliers were the only class of enzymes of real commercial importance. Then the use of amylases, lipases, and cellulases as detergent ingredients started to take off during the 1980s and grew steadily in importance during the 1990s. Just after the turn of the century, two new enzyme classes entered the detergent market: mannanases and pectate lyases.

Current trends for enzymes within detergents

The application of enzymes in detergents makes up the largest single segment of the world market for industrial enzymes. In 2003, the potential market for detergent enzymes was approximately US$700 million, of which Novozymes had a share of more than 56%. Enzymes on average constitute about 3-5 % of the total raw material costs of detergents – but very different from region to region. By far the largest volume of detergent enzymes is used in “heavy-duty” laundry detergents for household use (powders, liquids, and also tablets). There is also some penetration into “light-duty”laundry products for the washing of delicate fabrics although some enzymes are too aggressive for wool and silk. The main task of enzymes in laundry detergents is to remove stains of animal or plant origin. Another important task is to prevent soils from spreading throughout the laundry by redeposition.

This benefit is often referred to as “general cleaning” or “whiteness maintenance.”Enzymes also provide care effects by acting directly on cotton surfaces, helping garments look new longer. Repeatedly worn and washed laundry items are often contaminated with invisible residues, especially if they have been washed with detergents containing few enzymes. The residues make textile fibers sticky, attracting soil from the wash water, which results in incomplete cleaning. Multi-enzyme systems efficiently prevent this buildup of soil deposits. Automatic dishwashing detergents for household use are another increasingly important market segment. The enzyme penetration is highest in Europe, followed by the United States, where the market is growing. In industrialized countries the leading detergent brands typically contain more than one class of enzymes. Food stains are complex substrates containing protein, starch, and fat all mixed together. By combining different enzymes, soils are removed more efficiently, utilizing synergies between each enzyme’s cleaning abilities.

Trends driving enzyme usage

The importance of enzymatic detergency is expected to continue to increase, based on the following trends:

- Reduction of washing temperatures (mainly Europe)

- More detergents without bleach (e.g., color detergents and liquid detergents)

- More compact detergent formulations

- More cost-effective enzymes

Thanks to modern genetic engineering technology, enzymes are becoming increasingly cost efficient and offer higher yields. There are also possibilities to commercialize “custom-made” enzymes with improved economy and application properties.

On the other hand, detergents in most developed markets are facing price erosion, and consequently manufacturers are increasing their efforts to reduce ingredient costs. Competition between leading brands and cut-price supermarket-owned private label detergents may therefore limit the scope for further development in enzyme usage.

To some extent enzymes compete with surfactants; and considerable efforts are made by, for example, Novozymes to demonstrate that reducing enzymes in favor of surfactants typically does not pay off for customers. There are still sizable potential markets in developing countries where the penetration of enzymes is low, but these markets will gradually expand in line with the rising level of economic development.

Other markets where enzymes have low penetration are detergents for professional laundries and automatic dishwashing in institutions and restaurants. Owing to very high requirements for speed and cleaning efficiency, these market segments use strong chemicals, which have low compatibility with enzymes. Enzymes are, however, still used in their original application the prewashing of blood-stained laundry from hospitals and slaughterhouses.

Key Challenges for enzymes used in detergents

One of the key challenges of enzymes is that they are more sensitive to environmental factors than conventional surfactants and detergents and tend to lose their effectiveness when exposed to high temperatures and harsh chemicals. Both the producer and customer must take into account storage stability requirements such as stability of enzyme activity, microbial stability, physical stability, and the formulation of the enzyme product itself.

All modern detergents face a long journey before they actually are used in the consumers’ washing machines. The most important steps are:

- Production. In production, it is crucial that the detergent has the optimal formulation to reach its destination with performance intact.

- Warehouse. Storage conditions can be tough on detergent formulations. The detergent may sit in a warehouse for a long time, and conditions such as temperature and humidity may lead to efficiency loss.

- Transportation. Transportation time and storage conditions vary greatly for all detergents. And as in the warehouse, transportation conditions can affect detergent efficiency.

- Retailer. All detergent producers would like their product to move quickly. The reality, however, is that detergents can sit on the shelf for a long time before purchase, again leading to less efficiency.

- Consumer. At the final stage, it is crucial that the consumer stores the detergent under optimal conditions and uses it in the right way, for example, correct dosing, appropriate washing temperature, and correct washing cycle. Altogether, modern detergents are complex and innovative products. Promotional pack sizes, transportation, and storage mean that it may take a long time before the detergent is actually used, and this fact challenges producers to deliver a detergent that performs consistently after its long journey to the consumers’ washing machines.

Novel stability enzymes technology

Late in 2013, Novozymes introduced a new range of highly robust and stable enzymes enabling detergent producers to deliver more consistent wash performance. Th e range of new enzyme technology also gives manufacturers even greater formulation flexibility, and it has the brand name Evity®. Evity® is the brand for new range of robust and stable enzymes for liquid and powder detergents.

Protease inhibitor in liquid detergents

For liquid detergents Evity® has a new improved boron-free protease inhibitor. The new inhibitor solution makes the protease fully active in the detergent while inhibiting the enzyme while being in the bottle. Improvements in liquid stability have significant advantages for detergent producers, as they pave the way for leveraging enzymes in detergents. The new inhibitor developed by Novozymes is far more efficient than existing boron-based stabilization systems enabling the inclusion of multiple enzymes in the detergent as well as greater formulation flexibilities with other detergent ingredients.

Tests conducted by Novozymes on different European Union (EU) mid-tier liquid laundry detergents, washing under conditions of 40°C, 75 g/14 L wash, 15°dH - water hardness and samples stored at 30°C, show superior wash performance on individual protease stains after storage. In total, the novel enzyme technology from Novozymes provides these improvements for liquid detergents:

- Increased protease wash performance after storage

- Increased multi-enzyme performance after storage

- Greater formulation flexibility with other detergent ingredients

- Completely boron-free liquid detergent formulations with great performance

New granulate enzyme technology

For powder detergents, Evity® builds on a new granulate enzyme technology to improve stability of the detergent – laundry as well as automatic dishwash detergents. Granulate enzyme technology simply means that the enzyme concentrate is processed into a granule. This is done to prolong their working life; such immobilized enzymes may go on working for over a year—and even longer. Coating of the enzyme granulate protects the enzyme further from deactivation by other ingredients in the detergents, such as surfactants.

Tests conducted by Novozymes on an EU front-loader under conditions of 40°C, 15°dH, detergent containing bleach, dosage of 65 - 110 g/14 L wash found that standard protease shows great residual wash performance after regular accelerated storage conditions, while protease with the new stabilizer is superior also after tough accelerated conditions. With the new enzyme stabilization capabilities marketed by Novozymes starting in late 2013, these improvements for granulated enzymes used in detergents have been provided for the industry:

- Wash performance also after storage at tough conditions

- Consistent wash performance, which promotes brand loyalty for the detergent producer

- Longer-lasting, enhanced wash performance via single or multiple enzymes

- Visible and better performance—which is key for consumers.

Find out more about the power of enzymes

Enzymes in Modern Detergents

Series: Methods In Biotechnology > Book: Microbial Enzymes and Biotransformations

Protocol | DOI: 10.1385/1-59259-846-3:151

Huge amounts of alkaline enzymes are used in the detergent industry, and they have been widely incorporated into heavy-duty laundry and automatic dishwashing detergents. The alkaline enzymes used in modern detergents are protease, cellulase,

Huge amounts of alkaline enzymes are used in the detergent industry, and they have been widely incorporated into heavy-duty laundry and automatic dishwashing detergents. The alkaline enzymes used in modern detergents are protease, cellulase, α-amylase, lipase, and mannanase. In this chapter, methods for screening alkaline enzyme-producing alkaliphilic Bacillus strains, enzyme assays, purification, properties, and genetics of enzymes are described.

Figures ( 0 ) & Videos ( 0 )

Experimental specifications, other keywords.

Citations (8)

Related articles, transcriptome-wide identification of 2′- o -methylation sites with riboxi-seq, rna remodeling by rna chaperones monitored by rna structure probing.

Mitochondrial Genome and Plant Taxonomy

In vitro footprinting of promoter regions within supercoiled plasmid dna, familial adenomatous polyposis, te-based mutagenesis systems in plants, mutational analysis of p53 in human tumors, nonradioactive pcr sequencing using digoxigenin, identification of mtdna mutations in human cancer, methylation-sensitive restriction fingerprinting.

- Houston, J. H. (1997) Detergent enzymes’ market, in Enzymes in Detergency (van Ee, J. H., Misset, O., and Baas, E. J., eds.), Marcel Dekker, New York, pp. 11–21.

- Bott, R. (1997) Development of new proteases for detergents, in Enzymes in Detergency (van Ee, J. H., Misset, O., and Baas, E. J., eds.), Marcel Dekker, New York, pp. 75–91.

- Saeki, K., Okuda, M., Hatada, Y., Kobayashi, T., Ito, S., Takami, H., and Horikoshi, K. (2000) Novel oxidatively stable subtilisin-like serine proteases from alkaliphilic Bacillus spp.: Enzymatic properties, sequences, and evolutionary relationships. Biochem. Biophys. Res. Commun. 279 , 313–319.

- Saeki, K., Hitomi, J., Okuda, M., Hatada, Y., Kageyama, Takaiwa, M., et al. (2002) A novel species of alkaliphilic Bacillus that produces an oxidatively stable alkaline serine protease. Extremophiles 6 , 65–72.

- Ito, S. (1997) Alkaline cellulases from alkaliphilic Bacillus: Enzymatic properties, genetics, and application to detergents. Extremophiles 1 , 61–66.

- Hoshino, E. and Ito, S. (1997) Application of alkaline cellulases that contribute to soil removal in detergents, in Enzymes in Detergency (van Ee, J. H., Misset, O., and Baas, E. J., eds.), Marcel Dekker, New York, pp. 149–174.

- Hakamada, Y., Koike, K., Yoshimatsu, T., Mori, H., Kobayashi, T., and Ito, S. (1997) Thermostable alkaline cellulase from an alkaliphilic isolate, Bacillus sp. KSM-S237. Extremophiles 1 , 151–156.

- UpaDek, H. and Kottwitz, B. (1997) Application of amylases in detergents, in Enzymes in Detergency (van Ee, J. H., Misset, O., and Baas, E. J., eds.), Marcel Dekker, New York, pp. 203–212.

- Hagihara, H., Igarashi, K., Hayashi, Y., Endo, K., Ikawa-Kitayama, K., Ozaki, K., et al. (2001) Novel α-amylase that is highly resistant to chelating reagents and chemical oxidants from the alkaliphilic Bacillus isolate KSM-K38. Appl. Environ. Microbiol. 67 , 1744–1750.

- Kobayashi, T., Hakamada, Y., Adachi, S., Hitomi, J., Yoshimatsu, T., Koike, K., et al. (1995) Purification and some properties of an alkaline protease from alka-lophilic Bacillus sp. KSM-K16. Appl. Microbiol. Biotechnol. 43 , 473–481.

- Lowry, O. H., Rosebrough, N. J., Farr, A. L., and Randall, J. R. (1951) Protein measurement with the Folin phenol reagent. J. Biol. Chem. 242 , 265–275.

- Taber, H. W. and Sherman, F. (1964) Spectrophotometric analyzers for disk elec-trophoresis: Studies of yeast cytochrome c. Ann. NYAcad. Sci. 121 , 600–615.

- Hakamada, Y., Kobayashi, T., Hitomi, J., Kawai, S., and Ito, S. (1994) Molecular cloning and nucleotide sequence of the gene for an alkaline protease from the alka-lophilic Bacillus sp. KSM-K16. J. Ferment. Bioeng. 78 , 105–108.

- Saito, H. and Miura, K. (1963) Preparation of transforming deoxyribonucleic acid by phenol treatment. Biochim. Biophys. Acta 72 , 619–629.

- Chang, S. and Cohen, S. N. (1979) High frequency transformation of Bacillus sub-tilis. Mol. Gen. Genet. 168 , 111–115.

- Birnboim, H. C. and Doly, J. (1979) A rapid alkaline extraction procedure for screening recombinant plasmid DNA. Nucleic Acids Res. 7 , 1513–1523.

- Yoshimatsu, T., Ozaki, K., Shikata, S., Ohta, Y., Koike, K., Kawai, S., and Ito, S. (1990) Purification and characterization of alkaline endo-1,4-β-glucanases from alkalophilic Bacillus sp. KSM-635. J. Gen. Microbiol. 136 , 1973–1979.

- Ozaki, K., Shikata, S., Kawai, S., Ito, S., and Okamoto, K. (1990) Molecular cloning and nucleotide sequence of a gene for alkaline cellulase from Bacillus sp. KSM-635. J. Gen. Microbiol. 136 , 1327–1334.

- Hakamada, Y., Hatada, Y., Koike, K., Yoshimatsu, T., Kawai, S., Kobayashi, T., and Ito, S. (2000) Deduced amino acid sequence and possible catalytic residues of a thermostable, alkaline cellulase from an alkaliphilic Bacillus strain. Biosci. Biotechnol. Biochem. 64 , 2281–2289.

- Fukumori, F., Kudo, T., Narahashi, Y., and Horikoshi, K. (1986) Molecular cloning and nucleotide sequence of the alkaline cellulase gene from the alkalophilic Bacillus sp. strain 1139. J. Gen. Microbiol. 132 , 2329–2335.

- Sumitomo, N., Ozaki, K., Kawai, S., and Ito, S. (1992) Nucleotide sequence of the gene for an alkaline endoglucanase from an alkalophilic Bacillus and its expression in Escherichia coli and Bacillus subtilis. Biosci. Biotechnol. Biochem. 56 , 872–877.

- Igarashi, K., Hatada, Y., Hagihara, H., Saeki, K., Takaiwa, M., Uemura, T., et al. (1998) Enzymatic properties of a novel liquefying α-amylase from an alkalophilic Bacillus isolate and entire nucleotide and amino acid sequences. Appl. Environ. Microbiol. 64 , 3282–3289.

Advertisement

Center for Research on Ingredient Safety

Trending – laundry detergent enzymes.

Elisabeth Anderson <[email protected]> ; Joe Zagorski <[email protected]> - September 26, 2022

Ever wonder what makes laundry detergent so effective? In this post, we explore a common ingredient that helps boost detergent performance, enzymes.

What are enzymes

Why are enzymes useful?

Enzymes target specific types of stains and break them down quickly and effectively. For example, some enzymes will target proteins, starches, or fats and help break down and remove those ingredients quickly. Enzymes work better than soap alone because they can break down specific stains effectively without needing hot water. Modern laundry detergents contain enzymes optimized for washing clothes in cold water while using less water, making detergents containing enzymes better for the environment and more effective at cleaning clothes.

What kinds of enzymes are found in laundry detergent?

There are many types of enzymes found in laundry detergents here are the most common ones ( 1 , 2 , 3 , 4 ):

- Amylases remove starch stains such as pasta, potatoes, and more.

- Cellulases provide color care for fabric and help remove soils, clay, rust, and more.

- Lipases remove lipid (fat) stains such as butter, oil, and more.

- Mannanases remove mannan-containing stains such as barbecue sauce, chocolate, ice cream, and more.

- Proteases remove protein stains such as grass, eggs, bodily fluids, and more.

Are enzymes found in laundry detergent harmful to my health?

It’s known that some enzymes can trigger allergic reactions, especially if inhaled in large quantities. So, scientists looked at how enzymes in modern detergents (post-1971) could potentially cause allergic reactions or adverse health impacts ( 1 , 2 , 3 ). Scientists looked at the exposure routes , focusing on inhalation and skin contact. The research shows that enzymes found in modern detergents used for washing clothes do not trigger allergic reactions from either inhalation or skin contact ( 1 , 2 , 3 ). Enzymes in laundry detergent are overwhelmingly safe and effective. If someone is experiencing a reaction to a laundry detergent, they’re likely impacted by a fragrance or other ingredient rather than an enzyme used in the formulation.

What’s the risk?

We know that modern detergents are formulated with enzymes and other ingredients that allow clothes washing to be environmentally friendly by reducing the water needed for washing and eliminating the need for hot water, which reduces the energy needed to do each load of laundry. Based on the currently available science, enzymes do not pose a risk to our health and are safe when found in properly formulated detergents. Given the information we have, we know we can safely wash clothes without the risk of adverse health outcomes from enzymes while doing our part to reduce water and energy usage.

The good news.

You do not need to make your own laundry detergent to have a safe, effective product. The enzymes found in modern detergents break down stains and clean laundry without adversely impacting our health.

Did you find this article useful?

new - method size: 3 - Random key: 1, method: tagSpecific - key: 1

You Might Also Be Interested In

Science Day 2023 – New Approach Methodologies in Support of Weight of Evidence Assessments for Regulatory Decisions

SOT FDA Colloquia—The Evolving Science in Developmental Immunology and Immunotoxicity

Science symposium: plastic recycling & chemical contaminants in recycled plastic, rather than being ‘scared,’ consumers should look for the evidence and make informed decisions.

Published on August 1, 2017

MSU Center Focusing on Ingredient Safety

Published on April 27, 2017

Summer Staple – Pectin

Published on July 8, 2019

- center for research on ingredient safety

- enzymes detergent

- enzymes laundry

- enzymes laundry pod

- laundry pod

- center for research on ingredient safety,

- enzymes detergent,

- enzymes laundry,

- enzymes laundry pod,

The Science Behind Detergent Enzymes: How They Break Down Dirt and Grime

by Infinita423biotech | May 31, 2024 | Detergent Enzymes | 0 comments

Detergent enzymes have revolutionized the cleaning industry, providing a powerful and efficient way to break down dirt and grime. Understanding the science behind these enzymes is crucial in appreciating their effectiveness and potential for future developments. In this article, we will explore the role of detergent enzymes, their chemistry, the process of stain removal, the benefits of enzyme-based detergents, and the exciting advancements on the horizon.

Understanding Detergent Enzymes

Detergent enzymes are biological molecules that act as catalysts in the breakdown of tough stains and dirt. These enzymes are naturally occurring proteins that speed up chemical reactions without being consumed in the process. By targeting specific molecules found in stains, they enhance the cleaning power of detergents.

What are Detergent Enzymes?

Detergent enzymes are specialized proteins produced by living organisms, such as bacteria and fungi. These enzymes possess unique shapes and structures that enable them to interact with specific target molecules. Different types of detergent enzymes have varying functions, allowing for targeted stain removal.

One fascinating aspect of detergent enzymes is their ability to work in a wide range of environmental conditions. For example, some enzymes are effective in both high and low temperatures, making them versatile for use in various laundry settings. Additionally, these enzymes are biodegradable, making them environmentally friendly compared to harsh chemical cleaners.

The Role of Enzymes in Cleaning Products

Enzymes play a crucial role in cleaning products by breaking down complex stains into smaller, more manageable compounds. They do this by catalyzing chemical reactions that would otherwise occur slowly or not at all. The use of enzymes in detergents enhances the overall cleaning performance.

Moreover, enzymes in detergents are highly specific in their actions, targeting only the molecules present in stains without affecting the surrounding fabric. This specificity helps prevent damage to clothing fibers while effectively removing dirt and grime. As a result, detergent enzymes are not only efficient but also gentle on fabrics, prolonging the lifespan of garments.

The Chemistry of Detergent Enzymes

The effectiveness of detergent enzymes lies in their intricate chemical properties and mechanisms of action. Understanding the chemistry behind these enzymes is essential in designing more efficient cleaning products.

Enzymes are biological catalysts that speed up chemical reactions without being consumed in the process. In the case of detergent enzymes, they play a crucial role in breaking down complex stains into smaller, more manageable components. This breakdown process is highly specific, as each enzyme is designed to target a particular type of stain, ensuring maximum efficiency in stain removal.

The Mechanism of Enzyme Action

Detergent enzymes work by binding to specific molecules in stains and facilitating the breakdown of chemical bonds. This process, known as the enzymatic reaction, occurs at the active site of the enzyme. The enzyme undergoes a series of conformational changes, allowing it to convert the stain molecules into simpler forms that can be easily washed away.

Moreover, enzymes are incredibly efficient in their action, often working at lower temperatures than traditional chemical detergents. This not only helps in reducing energy consumption during the washing process but also contributes to a more sustainable approach to cleaning.

Different Types of Enzymes Used in Detergents

Different types of enzymes are used in detergents , and each has its own specific function. Protease enzymes target protein-based stains like grass, blood, and food stains. Lipase enzymes break down fatty substances like grease and oil. Amylase enzymes target starch-based stains, such as those caused by sauces or fruits.

By combining these different enzymes in varying proportions, detergent manufacturers can create products that are tailored to address a wide range of stains effectively. This versatility makes enzyme-based detergents a popular choice for consumers looking for powerful cleaning solutions that are also environmentally friendly.

How Detergent Enzymes Break Down Dirt and Grime

The process of stain removal with detergent enzymes involves a series of steps that effectively eliminate stubborn dirt and grime.

Understanding the intricate process of how detergent enzymes work to break down dirt and grime can provide valuable insights into effective stain removal techniques. Enzymes are biological molecules that act as catalysts, speeding up chemical reactions without being consumed in the process. In the case of detergent enzymes, their specific functions target different types of stains, making them highly effective in removing tough grime from various surfaces.

The Process of Stain Removal

When detergent-containing enzymes are applied to a stain, the enzymes identify and bind to the specific molecules responsible for the stain. The enzymes then break down these molecules into smaller compounds through the catalytic reaction. This breakdown process weakens the stain’s structure, making it easier to be washed away during rinsing.

Furthermore, the enzymatic action not only helps in removing visible stains but also aids in eliminating odor-causing molecules that may be embedded in the fabric. This dual functionality of detergent enzymes ensures a thorough cleaning process, leaving fabrics not only looking clean but also smelling fresh.

Enzymes and Tough Stains

Tough stains, such as those from red wine or chocolate, can be particularly challenging to remove. However, detergent enzymes excel in tackling these stubborn stains. Protease enzymes break down the protein-based components, while lipase enzymes target the grease or oil components. Amylase enzymes, on the other hand, efficiently break down starch-related stains.

By utilizing a combination of enzymes tailored to specific types of stains, modern detergents have become increasingly effective in removing even the most stubborn grime. This targeted enzymatic approach not only enhances the cleaning performance of detergents but also helps in preserving the quality of fabrics by minimizing the need for harsh chemicals or vigorous scrubbing.

The Benefits of Enzyme-Based Detergents

Enzyme-based detergents offer several advantages over traditional cleaning products, making them a popular choice for many consumers.

When it comes to enzyme-based detergents, the benefits extend far beyond just effective cleaning. These innovative products are formulated to target specific types of stains, such as protein-based stains like blood or grass, and break them down at a molecular level. This targeted approach not only ensures thorough stain removal but also helps preserve the fabric fibers, extending the lifespan of your favorite garments.

Efficiency and Effectiveness of Enzyme Detergents

Enzyme-based detergents are highly efficient in stain removal, allowing for cleaner and fresher clothes. The targeted action of enzymes ensures that even stubborn stains are effectively broken down, giving exceptional cleaning results.

Moreover, the use of enzymes in detergents can also help prevent graying and fading of fabrics over time. By effectively removing dirt and grime without the need for harsh chemicals, enzyme-based detergents help maintain the vibrancy and brightness of your clothing, keeping them looking newer for longer.

Environmental Impact of Enzyme Detergents

Another significant benefit of enzyme-based detergents is their reduced environmental impact. These detergents often require lower washing temperatures and shorter washing cycles, resulting in energy savings. Additionally, enzyme-based detergents are usually biodegradable, making them a more eco-friendly choice.

By choosing enzyme-based detergents, consumers can contribute to reducing water and energy consumption during the laundry process, ultimately lowering their carbon footprint. The biodegradable nature of these detergents ensures that they break down into harmless byproducts after use, minimizing their impact on the environment and water systems.

Future Developments in Detergent Enzymes

As technology advances, new developments in detergent enzymes are on the horizon, promising even greater cleaning capabilities and sustainability.

Enzymes have long been recognized for their ability to break down tough stains and odors, making them a key ingredient in modern laundry detergents. However, the quest for innovation in enzyme technology continues as researchers strive to unlock new potentials in this field.

Innovations in Enzyme Technology

Ongoing research into enzyme technology aims to optimize the performance of detergent enzymes. Scientists are exploring ways to engineer enzymes with enhanced stability and activity, ensuring better cleaning results with reduced enzyme usage.

One exciting area of development is the use of bioinformatics and computational modeling to design enzymes with specific properties tailored for different cleaning tasks. By understanding the molecular structure of enzymes at a deeper level, researchers can fine-tune their characteristics for optimal performance in various detergent formulations.

Potential Challenges and Solutions

While the future of detergent enzymes holds great promise, there are challenges that need to be addressed. One challenge is ensuring compatibility with different fabric types. Researchers are actively working on developing enzymes that are gentle yet effective on all types of fabrics to avoid any potential damage.

Another hurdle to overcome is the stability of enzymes in different washing conditions. Enzymes can be sensitive to factors such as pH, temperature, and the presence of other chemicals in the detergent formulation. Finding ways to enhance the resilience of enzymes under varying conditions is crucial for maintaining their effectiveness over time.

In conclusion, detergent enzymes play a vital role in breaking down dirt and grime. Understanding their science and chemistry helps us appreciate their effectiveness in stain removal. Enzyme-based detergents offer numerous benefits, from improved efficiency to reduced environmental impact. With ongoing advancements in enzyme technology, the future of detergent enzymes looks brighter than ever, paving the way for more efficient and sustainable cleaning solutions.

- Agriculture Enzymes

- Animal Feed Enzymes

- Brewery Enzymes

- Cellulase Complex Enzymes For Cellulosic Ethanol

- Detergent Enzymes

- Disinfectants

- Distillery Enzymes

- Enzymes for Biodiesel

- Enzymes For Ceramic Industry

- Enzymes for Cosmetics

- Enzymes for Crude Oil Spill Remediation

- Enzymes For Hydrolysis Of Gel Used In Crude Oil Extraction

- Enzymes for Malt

- Enzymes for soil stabilization

- Food and Beverage Enzymes

- Juice Extraction Enzymes For Wine

- Pharmaceutical Enzymes

- Pulp and Paper Enzymes

- Starch Processing Enzymes

- Sugar Processing Enzymes

- Textile Enzymes

- Wastewater Treatment Enzymes

WhatsApp us

- Laundry Detergents

- Fine Mesh Laundry Bags

Natural Wool Dryer Balls

The Laundry Lowdown Blog

- About Our Ingredients

- Call us at 800-977-1841

Silk & Wool Detergents

- Fragrance Free

- Lavender Mist

- Spring Magnolia

All-Purpose Detergents

- Shore Breeze

Activewear Detergent

*NEW* Laundry detergent designed to enhance laundry cleaning for your workout wear. Transform your sweaty and stained sports wear to a new level of clean.

Shop Refill Packs

Shop Trial Size Bottles

Stock Your Suds

Naturally Bright Oxygen Laundry Powder

Enhance your laundry routine to brighten and restore your fabrics.

Shop All Detergents

Premium Mesh Laundry Bags

Shop All Laundry Accessories

Ingredients

About Heritage Park

How Enzymes in Laundry Detergent Break Down and Remove Tough Stains

- by Mary Babinski

- November 09, 2021

If you’re looking for a natural way to clean fine fabrics without causing damage, an enzyme laundry detergent could be right for you. Enzymes are a highly effective laundry stain remover that won’t harm delicates, including clothing and household linen. But to make the most of any enzyme laundry detergent, you need to know a bit about what enzymes are and how they work.

Here at Heritage Park , our Luxury All-Purpose Detergent contains a proprietary blend of enzymes; it is a concentrated, pH-neutral formula that is wonderful for removing stains from delicate fabric. Let’s take a closer look at what enzymes are and how they work in your wash.

What Are Laundry Enzymes?