Examples of Strategic Management: Learn from Industry Leaders

Welcome to the world of strategic management, where businesses navigate the complex landscape of competition, innovation, and growth. In this comprehensive guide, we’ll delve into the fascinating realm of strategic management by exploring real-world examples of how some of the most successful companies and organizations have used strategic thinking to achieve remarkable results.

Strategic management is the art and science of formulating, implementing, and evaluating cross-functional decisions that enable an organization to achieve its long-term objectives. It’s a critical aspect of business leadership, driving sustainable success and ensuring that companies not only survive but thrive in dynamic markets.

Our journey will take us through various sectors, from technology giants and automotive pioneers to startups, nonprofits, and government entities. By examining both successes and failures, you’ll gain valuable insights into the principles and practices of strategic management, allowing you to apply these lessons to your professional endeavors.

So, without further ado, let’s embark on this enlightening exploration of strategic management through the lens of remarkable examples from the business world.

Strategy Management

Strategy management is the systematic process of formulating, implementing, and evaluating strategies to achieve organizational goals and sustain a competitive advantage.

Understanding Strategic Management

Before we dive into the captivating examples of strategic management, let’s establish a solid understanding of what strategic management entails.

Strategic management is the comprehensive process of defining an organization’s direction, making decisions decisions on allocating its resources to pursue this direction and guiding the implementation of these decisions .

It’s not a one-time task but rather an ongoing, dynamic process that aligns an organization’s internal capabilities with the demands of its external environment.

Key Components of Strategic Management

- Setting Clear Objectives: Strategic management begins with establishing clear, specific, and measurable objectives. These objectives provide a sense of purpose and direction for the entire organization.

- Environmental Analysis: Understanding the business environment is crucial. This includes analyzing industry trends, competitive forces, market dynamics, and potential risks and opportunities.

- Strategy Formulation: Once the organization’s objectives are defined and the external environment is assessed, the next step is developing a strategy. This involves determining how the organization will achieve its objectives, often considering factors like differentiation, cost leadership, or niche focus.

- Strategy Implementation: Formulating a strategy is only the first step; implementing it is equally important. This phase involves aligning the organization’s structure, processes, people, and culture with the chosen strategy.

- Evaluation and Control: Continuous evaluation and control mechanisms are necessary to ensure that the chosen strategy is producing the desired results. If not, adjustments may be required.

Now that we have a solid foundation in place, let’s explore how these principles are put into action with real-world examples of strategic management across diverse industries.

Strategic Management Frameworks and Tools

Strategic management involves the use of various frameworks and tools to analyze, plan, and execute strategies effectively. Understanding these tools is essential for any business professional.

Here are some of the most commonly used ones:

1. SWOT Analysis: A framework that helps organizations identify their Strengths, Weaknesses, Opportunities, and Threats. It’s a fundamental tool for strategic planning .

2. PESTEL Analysis: This tool evaluates the Political, Economic, Sociocultural, Technological, Environmental, and Legal factors that can impact an organization.

3. Porter’s Five Forces: Developed by Michael Porter, this framework assesses the competitive forces within an industry, helping organizations determine their competitive position.

4. BCG Matrix: It’s a portfolio analysis tool that helps organizations assess their product offerings and allocate resources effectively. Products are categorized as Stars, Cash Cows, Question Marks, or Dogs.

5. Balanced Scorecard: This performance measurement framework considers financial and non-financial factors, allowing organizations to track progress toward their strategic goals.

6. Scenario Planning: In an uncertain environment, scenario planning involves creating multiple future scenarios to prepare for various outcomes.

7. Key Performance Indicators (KPIs): These are specific metrics that organizations track to measure progress toward strategic objectives.

The 5 Phases of the Strategic Management Process

Strategic management is a comprehensive and iterative process that guides organizations in making informed decisions , formulating strategies, implementing them effectively, and evaluating their outcomes.

Understanding the various phases of the strategic management process is essential for achieving strategic objectives.

Let’s delve into each phase:

Examples of Strategic Management in Action

In this section, we’ll delve into captivating examples of strategic management from various sectors. These case studies offer valuable insights into how organizations leverage strategic thinking to thrive in competitive markets, innovate, and adapt to changing circumstances.

Stay tuned as we explore the strategic moves and decisions made by industry leaders that have shaped their success.

1. Strategic Management at Apple Inc.

Our first stop on this tour of strategic management excellence is none other than Apple Inc. Founded in 1976, Apple has become a household name synonymous with innovation and cutting-edge technology.

Apple’s Strategic Vision: Apple’s co-founder, Steve Jobs, was known for his visionary approach to product development. He famously said, “Innovation distinguishes between a leader and a follower.”

Apple’s strategic management has been deeply rooted in this philosophy, focusing on creating products that are not just technologically advanced but also beautifully designed and user-friendly.

Key Strategic Moves:

- Product Diversification: Apple started as a computer company, but it didn’t stop there. The introduction of the iPod, iPhone, iPad, and Apple Watch showcased Apple’s ability to diversify its product portfolio strategically.

- Ecosystem Integration: Apple’s ecosystem is a prime example of strategic management. The seamless integration between devices, software (iOS, macOS), and services (Apple Music, iCloud) fosters customer loyalty and increases brand stickiness.

- Retail Strategy: Apple’s retail stores are strategically positioned in high-traffic locations, offering not just products but experiences. The design of Apple Stores, along with well-trained staff, creates a unique customer journey.

- Supply Chain Mastery: Efficient supply chain management allows Apple to deliver products to customers promptly. The company’s ability to source components globally and assemble them on time is a strategic advantage.

- Brand Image: Apple has meticulously cultivated its brand image as an innovator that challenges the status quo. This strategic positioning has helped Apple command premium prices for its products.

Takeaway: Apple’s strategic management demonstrates the importance of a clear vision, innovation, diversification, and a relentless focus on the customer experience.

2. Toyota: Pioneering Operational Excellence

Our next example hails from the automotive industry, and it’s none other than Toyota. Toyota’s approach to strategic management has revolutionized manufacturing processes and set new standards for operational efficiency.

Toyota’s Strategic Vision: Toyota’s vision revolves around “delivering better products and better services.” Its strategic management is grounded in the philosophy of “continuous improvement” or Kaizen.

- Lean Manufacturing: Toyota pioneered the concept of lean manufacturing, aiming to reduce waste, increase efficiency, and improve quality. The Toyota Production System (TPS) is a renowned example of strategic management focused on operational excellence.

- Global Expansion: Toyota strategically expanded its operations globally, becoming one of the largest automakers in the world. Its diverse product range caters to different markets and customer segments.

- Innovation in Hybrid Technology: Toyota’s introduction of the Prius, the world’s first mass-produced hybrid car, showcased its strategic commitment to sustainability and innovation.

- Quality Control: Toyota’s relentless pursuit of quality and its “stop the line” policy emphasizes its commitment to delivering exceptional products.

- Supply Chain Resilience: Toyota’s strategic management includes building a resilient supply chain. This was evident when the company navigated supply chain disruptions caused by Japan’s 2011 earthquake and tsunami.

Takeaway: Toyota’s strategic management teaches us the importance of operational excellence, continuous improvement, and a long-term commitment to quality and sustainability.

3. Airbnb: Disrupting the Hospitality Industry

Our final example brings us to the world of sharing economy and disruptive innovation—Airbnb.

Airbnb’s Strategic Vision: Founded in 2008, Airbnb’s strategic vision is to “create a world where anyone can belong anywhere.” It disrupted the traditional hospitality industry by leveraging technology to connect travelers with hosts offering unique accommodations.

- Platform-Based Model: Airbnb’s strategic management centers on its platform-based business model. It doesn’t own properties but provides a marketplace for hosts and guests to transact.

- Global Expansion: Airbnb strategically expanded its presence to become a global platform with listings in nearly every country. This expansion was supported by localization efforts and strategic partnerships.

- User-Centric Design: Airbnb’s focus on user experience and design thinking has been a strategic advantage. The platform is user-friendly, with features like reviews, secure payments, and personalized recommendations.

- Community Building: Airbnb strategically built a sense of community among hosts and guests through its branding and initiatives like host meetups and the “Airbnb Community Center.”

- Diversification: Over time, Airbnb strategically diversified its offerings beyond accommodations to include experiences and adventures, further enhancing its value proposition.

Takeaway: Airbnb’s strategic management illustrates the power of disruptive innovation, platform-based models, user-centric design, and the importance of building a strong community.

4. Amazon: Mastering Customer-Centricity

Amazon, the e-commerce giant founded by Jeff Bezos, epitomizes strategic management in the digital age. Its relentless focus on customer-centricity has propelled it to the forefront of the global retail industry.

Amazon’s Strategic Vision: Amazon’s vision is “to be Earth’s most customer-centric company, where customers can find and discover anything they might want to buy online.” Their strategic management revolves around leveraging technology to enhance customer experience.

- eCommerce Dominance: Amazon strategically disrupted the retail industry by pioneering e-commerce. They focused on providing customers with vast product selections, competitive prices, and convenient delivery options.

- Amazon Prime: The introduction of Amazon Prime, a subscription service offering free shipping and access to streaming services, was a strategic move that boosted customer loyalty and retention.

- Innovation Hub: Amazon’s strategic management includes heavy investments in innovation. They introduced the Kindle e-reader, Amazon Web Services (AWS), and Amazon Echo, expanding their reach into various tech sectors.

- Marketplace Model: Amazon’s strategic decision to allow third-party sellers on its platform broadened its product offerings and created a win-win situation for sellers and customers.

- Supply Chain Optimization: Amazon’s strategic brilliance extends to supply chain management, allowing them to fulfill orders efficiently. This includes investments in robotics and a vast distribution network.

Takeaway: Amazon’s strategic success highlights the significance of customer-centricity, innovation, and adaptability in today’s dynamic business landscape.

5. Coca-Cola: Branding Mastery

Coca-Cola, a global beverage giant, is renowned for its strategic management in brand building and marketing. It’s a classic example of how a company can turn a product into an iconic global brand.

Coca-Cola’s Strategic Vision: Coca-Cola’s vision is “to refresh the world in mind, body, and spirit.” Their strategic management revolves around creating an emotional connection with consumers through their brands.

- Brand Portfolio: Coca-Cola strategically expanded its brand portfolio beyond Coca-Cola to include a variety of beverages such as Diet Coke, Fanta, and Sprite, catering to diverse consumer preferences.

- Global Reach: Coca-Cola’s strategic global expansion made its products available in over 200 countries. This extensive reach bolsters its brand recognition and market presence.

- Marketing and Advertising: Coca-Cola’s iconic marketing campaigns, including the “Share a Coke” campaign and memorable Super Bowl ads, showcase its strategic emphasis on advertising and brand promotion.

- Sponsorships and Partnerships: Coca-Cola’s strategic partnerships with major sporting events like the FIFA World Cup and the Olympics demonstrate their commitment to associating their brand with positive experiences.

- Product Diversification: Recognizing evolving consumer preferences, Coca-Cola has strategically diversified its product offerings to include healthier options and reduced-sugar beverages.

Takeaway: Coca-Cola’s strategic management illustrates the power of branding, marketing, and diversification in building a globally recognized and cherished brand.

6. Netflix: Pioneering Digital Streaming

Netflix, the global streaming giant, is a prime example of a company that strategically disrupted the entertainment industry by transitioning from DVD rentals to digital streaming.

Netflix’s Strategic Vision: Netflix’s vision is “to become the best global entertainment distribution service, licensing entertainment content around the world.” Their strategic management focuses on providing high-quality content to subscribers.

- Content Creation: Netflix strategically shifted from being a content distributor to a content creator. Their original content, like “House of Cards” and “Stranger Things,” has garnered critical acclaim and subscriber loyalty.

- Global Expansion: Netflix strategically expanded globally, making its streaming service available in over 190 countries. This global reach is a testament to their strategic vision of becoming a global entertainment powerhouse.

- Data-Driven Personalization: Netflix’s strategic use of data analytics enables it to personalize content recommendations for each user, enhancing the viewing experience and subscriber retention.

- Subscription Model: Netflix’s strategic decision to adopt a subscription-based model allows it to generate steady revenue and invest heavily in content creation.

- Technology Investment: Netflix’s strategic investment in streaming technology ensures a seamless and high-quality streaming experience for subscribers.

Takeaway: Netflix’s strategic management highlights the significance of content creation, global expansion, data-driven personalization, and subscription-based revenue models in the digital entertainment industry.

7. Google: Dominating Online Search and Advertising

Google, led by Larry Page and Sergey Brin, is a strategic management powerhouse that transformed online search and digital advertising.

Google’s Strategic Vision: Google’s vision is “to provide access to the world’s information in one click.” Their strategic management revolves around organizing information and making it universally accessible and useful.

- Search Engine Dominance: Google’s strategic focus on delivering highly relevant search results and a user-friendly interface made it the world’s leading search engine.

- Advertising Model: Google’s strategic monetization through pay-per-click advertising, primarily through Google Ads (formerly AdWords), revolutionized digital advertising.

- Android Ecosystem: Google strategically developed the Android operating system, powering a significant portion of the world’s smartphones and expanding its ecosystem.

- Cloud Services: Google Cloud, part of Alphabet Inc. (Google’s parent company), is strategically positioned to compete in the cloud computing market.

- Innovation Ventures: Google’s strategic approach to innovation includes projects like Google X, focusing on moonshot technologies like self-driving cars, and Project Loon for internet connectivity in remote areas.

Takeaway: Google’s strategic management highlights the importance of search engine dominance, advertising revenue models, ecosystem development, and moonshot innovation.

8. Facebook (Meta Platforms): Connecting the World

Meta Platforms, formerly Facebook, under Mark Zuckerberg’s leadership, is a strategic management example that transformed social networking and digital communication.

Meta Platforms’ Strategic Vision: Meta’s vision is “to give people the power to build community and bring the world closer together.” Their strategic management centers on connecting people globally.

- User Base Expansion: Meta strategically expanded its user base by acquiring platforms like Instagram and WhatsApp, diversifying its social media portfolio.

- Advertising Monetization: Meta’s strategic monetization primarily relies on targeted advertising, offering advertisers extensive user data for precise targeting.

- Virtual Reality (VR) and Augmented Reality (AR): Meta is strategically investing in VR and AR technologies, envisioning a future of interconnected virtual experiences.

- Metaverse: The strategic focus on building the metaverse, a collective virtual shared space, aims to redefine digital interactions and experiences.

- Data Centers and Connectivity: Meta’s strategic investments in data centers and internet connectivity infrastructure support its global operations.

Takeaway: Meta Platforms’ strategic management emphasizes user engagement, advertising-driven revenue models, innovation in VR and AR, and the vision of a metaverse future.

9. Nike: Mastering Branding and Innovation

Nike, led by visionary figures like Phil Knight and Mark Parker, showcases strategic brand management and innovation in the sportswear industry.

Nike’s Strategic Vision: Nike’s vision is “to bring inspiration and innovation to every athlete in the world.” Their strategic management revolves around innovation, athlete endorsements, and brand identity.

- Iconic Branding: Nike’s strategic branding includes the creation of the famous “Swoosh” logo, making it one of the world’s most recognizable brands.

- Endorsement Deals: Nike’s strategic partnerships with athletes like Michael Jordan, LeBron James, and Serena Williams bolster brand recognition and aspiration.

- Innovation in Footwear: Nike’s strategic focus on footwear innovation, such as Air Max and Flyknit technologies, sets industry standards.

- Marketing Campaigns: Nike’s strategic marketing campaigns, like “Just Do It,” resonate with consumers and reinforce the brand’s message.

- Sustainability Initiatives: Nike’s strategic commitment to sustainability includes efforts like “Reuse-A-Shoe,” recycling old athletic shoes into sports surfaces.

Takeaway: Nike’s strategic management underscores the power of iconic branding, athlete endorsements, product innovation, emotionally resonant marketing, and sustainability in the sportswear sector.

10. Tesla: Revolutionizing Electric Vehicles

Tesla, spearheaded by visionary entrepreneur Elon Musk, represents a paradigm shift in the automotive industry and strategic management.

Tesla’s Strategic Vision: Tesla’s vision is “to create the most compelling car company of the 21st century by driving the world’s transition to electric vehicles.” Their strategic management revolves around sustainability, innovation, and disruption.

- Electric Vehicle (EV) Leadership: Tesla’s strategic focus on electric vehicles disrupted the automotive industry and accelerated the transition to sustainable transportation.

- Autonomous Driving: Tesla’s strategic integration of autonomous driving features, such as Autopilot, showcases a commitment to innovation and safety.

- Gigafactories: Tesla’s strategic establishment of Gigafactories globally ensures efficient EV production and battery technology development.

- Direct-to-Consumer Sales: Tesla’s strategic approach of selling directly to consumers disrupted traditional dealership models.

- Energy Solutions: Tesla’s strategic diversification into solar energy and energy storage with products like Solar Roof and Powerwall demonstrates a broader vision beyond EVs.

Takeaway: Tesla’s strategic management exemplifies the transformative power of innovation, sustainability, direct sales models, and diversification into complementary industries.

Examples of Strategic Failures

1. nokia: missed opportunities in the smartphone era.

Nokia, once an undisputed leader in mobile phones, serves as a notable example of strategic failure. While they had a strong market presence, Nokia failed to adapt to the smartphone revolution effectively.

Strategic Missteps:

- Lack of Innovation: Nokia was slow to innovate and adapt to changing consumer preferences. They stuck to their traditional mobile phone models while competitors were developing smartphones.

- Ignoring the Ecosystem: Nokia underestimated the importance of a robust app ecosystem, an area where Apple’s iOS and Google’s Android thrived.

- Ineffective Leadership: Frequent changes in leadership and organizational restructuring led to a lack of focus and direction.

Takeaway: Nokia’s downfall underscores the importance of innovation, adaptability, and staying attuned to market trends, even for industry leaders.

2. Blockbuster: Failing to Embrace Digital Streaming

Blockbuster, a giant in the video rental industry, faced a catastrophic strategic failure due to its inability to embrace digital streaming.

- Lagging Technology: Blockbuster was slow to adopt digital streaming technology and underestimated its potential.

- Failure to Adapt: While Netflix was disrupting the industry with its subscription-based streaming service, Blockbuster clung to its brick-and-mortar rental model.

- Missed Opportunities: Blockbuster had the chance to acquire Netflix early on but declined, which proved to be a costly decision .

Takeaway: Blockbuster’s demise highlights the critical importance of staying ahead of technological trends and being open to strategic partnerships.

3. Kodak: Missed the Digital Photography Wave

Kodak, a pioneer in photography, failed to adapt to the digital photography revolution, leading to a decline in its market presence.

- Overreliance on Film: Kodak was heavily reliant on film-based photography and underestimated the shift toward digital photography.

- Failure to Innovate: While they did develop digital camera technology, Kodak didn’t effectively commercialize it due to concerns about cannibalizing their film business.

- Lack of Vision: The company failed to envision a future where digital photography would dominate.

Takeaway: Kodak’s story emphasizes the importance of continuously innovating and not being afraid to disrupt your business model when necessary.

4. Blackberry: Ignoring the Smartphone Revolution

Blackberry, once synonymous with secure mobile communication, faltered when it failed to adapt to the rise of touchscreen smartphones.

- Innovation Gap: Blackberry’s failure to innovate and transition to touchscreen devices left it behind competitors like Apple and Samsung.

- Inadequate App Ecosystem: Blackberry’s app ecosystem couldn’t compete with the iOS App Store and Google Play Store.

- Complacency: Blackberry’s leadership was slow to recognize the competitive threat posed by touchscreen smartphones.

Takeaway: Blackberry’s decline underscores the need for established companies to remain agile and innovative in the face of evolving technologies and consumer preferences.

5. Xiaomi: Expanding Too Quickly

Xiaomi, a Chinese smartphone manufacturer, experienced a strategic setback when it expanded too rapidly into international markets.

- Overseas Expansion: Xiaomi aggressively expanded into markets outside China, including India and Europe, which stretched its resources.

- Supply Chain Issues: Rapid expansion led to supply chain challenges, including shortages of products in key markets.

- Brand Awareness: Xiaomi faced challenges in building brand awareness and trust outside China.

Takeaway: Xiaomi’s experience emphasizes the importance of measured, sustainable international expansion and the need for strong supply chain management.

These examples of strategic failures serve as cautionary tales, illustrating the significance of adaptability, innovation, foresight, and market awareness in the world of strategic management.

Lessons Learned from Strategic Management Examples

1. innovation is a game-changer.

- Key Lesson: Innovating in products, services, or business models can disrupt industries and create new market leaders.

- Examples: Apple’s continuous innovation in consumer electronics, Tesla’s pioneering electric vehicles, and Dollar Shave Club’s subscription-based razor service.

2. Customer-Centric Approach Pays Off

- Key Lesson: Prioritizing customer needs and preferences can lead to strong brand loyalty and business growth.

Examples: Amazon’s customer-centric e-commerce, Airbnb’s focus on user reviews and trust, and Warby Parker’s “Home Try-On” program.

3. Adaptability is Crucial

- Key Lesson: Being adaptable to changing market conditions and consumer trends is essential for long-term success.

- Examples: Netflix’s shift from DVD rentals to streaming, Slack’s evolution as a workplace collaboration platform, and Airbnb’s expansion into experiences.

4. Effective Marketing Matters

- Key Lesson: Creative and effective marketing strategies can generate significant attention and customer acquisition.

Examples: Dollar Shave Club’s viral marketing video, Airbnb’s storytelling approach, and Apple’s iconic advertising campaigns.

5. Ecosystem Development Drives Growth

- Key Lesson: Building an ecosystem of products, services, or partnerships can enhance value for customers and drive business growth.

Examples: Apple’s ecosystem of devices and services, Slack’s third-party integrations, and Tesla’s Supercharger network.

6. Sustainability is a Competitive Advantage

- Key Lesson: Incorporating sustainability and environmental responsibility into business strategies can attract socially conscious consumers and enhance brand reputation.

Examples: Tesla’s commitment to sustainable transportation, Airbnb’s Green Hosting program, and Patagonia’s eco-friendly practices.

7. Digital Transformation is Inevitable

- Key Lesson: Embracing digital technologies and online platforms is crucial in today’s business landscape.

Examples: Amazon’s digital retail dominance, Netflix’s streaming platform, and Tesla’s over-the-air software updates.

8. Diversification Reduces Risk

- Key Lesson: Diversifying product or service offerings can mitigate risk and expand revenue streams.

Examples: Tesla’s expansion into solar energy and energy storage, Amazon Web Services (AWS), and Apple’s ecosystem diversification.

9. Trust and Transparency Build Loyalty

- Key Lesson: Establishing trust through transparent practices and customer reviews can foster loyalty and credibility.

Examples: Airbnb’s user review system, Tesla’s commitment to safety and quality, and Amazon’s customer feedback-driven improvements.

10. Long-Term Vision is Essential

- Key Lesson: Maintaining a clear and ambitious long-term vision guides strategic decisions and sustains business growth.

- Examples: Amazon’s focus on long-term value over short-term profits, Tesla’s mission to accelerate the world’s transition to sustainable energy, and Apple’s dedication to innovation.

These lessons illustrate the diverse strategies and approaches employed by successful companies across various industries.

By studying these examples and applying the core principles to your own business, you can develop more effective strategic management practices and enhance your organization’s competitiveness and growth prospects.

In this comprehensive exploration of strategic management, we’ve dissected a multitude of examples, both successes and failures, from diverse industries. Through these cases, we’ve unearthed invaluable lessons that can guide businesses towards prosperity and sustainability.

Key takeaways include the paramount importance of innovation, adaptability, customer-centricity, and sustainability.

It’s not enough to merely acknowledge these lessons. To thrive in today’s competitive landscape, businesses must actively apply strategic management principles. Whether you’re a startup seeking growth, a corporate giant aiming to stay agile, or an organization striving for a brighter, more sustainable future, strategic management offers the compass to navigate these endeavors.

Lastly, it’s crucial to understand that strategic management is not static; it evolves alongside technology, market trends, and consumer behaviors. The examples we’ve examined serve as beacons of innovation and adaptation.

As we move forward, new case studies will emerge, reshaping our understanding of effective strategic management. Stay vigilant, stay adaptable, and continue learning from the ever-changing landscape of strategic management.

Tumisang Bogwasi

2X Award-Winning Entrepreneur | Empowering Brands to Generate Leads, Grow Revenue with Business Strategy and Digital Marketing | Founder, CEO of Fine Group

Related Posts

What is Strategic Management?

- July 3, 2023

How to Build a Business Strategy

- April 10, 2023

Trending now

Capturing the true value of Industry 4.0

In the past five years, a select group of companies have started pulling ahead in their efforts to implement Industry 4.0 across their manufacturing networks . Leading manufacturers are now realizing significant value from data and analytics, AI, and machine learning (ML). However, a large majority remain stuck in pilot purgatory, struggling to capture the full potential of their transformation efforts or deliver a satisfactory return on investment.

While digital transformations are notoriously difficult to scale up across networks of factories, the pressure to succeed is intense. Companies at the front of the pack are capturing benefits across the entire manufacturing value chain—increasing production capacity and reducing material losses, improving customer service and delivery lead times, achieving higher employee satisfaction, and reducing their environmental impact. Scaled across networks, these gains can fundamentally transform a company’s competitive position.

With so much at stake, manufacturers are putting significant time and money behind their digital transformations . These investments are paying off for some, but most remain unable to scale successful pilot programs or fully leverage new tools and technology to see meaningful returns.

This article explores some of the common pitfalls associated with digital transformations and how a more strategic and value-driven approach could help manufacturers in the race to get ahead.

Delivering value across every area of the factory

The digitally enabled factory of today looks very different from the leading factory of ten years ago. Advances in data and analytics, AI, and ML—and the array of technology vendors in the market—mean manufacturers can choose from hundreds of potential solutions and tech applications to improve their ways of working.

Implemented successfully, these solutions deliver irresistible returns. Across a wide range of sectors, it is not uncommon to see 30 to 50 percent reductions in machine downtime, 10 to 30 percent increases in throughput, 15 to 30 percent improvements in labor productivity, and 85 percent more accurate forecasting (Exhibit 1).

While digital transformations are notoriously difficult to scale up across networks of factories, the pressure to succeed is intense. Companies at the front of the pack are capturing benefits across the entire manufacturing value chain.

Digital transformations are revolutionizing all aspects of manufacturing, touching not just processes and productivity but also people. The right applications of technology can lead to more empowered decision making; new opportunities for upskilling, reskilling, and cross-functional collaboration; better talent attraction and retention; and improved workplace safety and employee satisfaction.

Customers see the impacts through reduced manufacturing lead times, right-first-time launch management, and improved customer service and complexity management. And, of course, there are the win–win advantages associated with reduced environmental impact, made possible through lower emissions and reduced waste and more efficient energy, water, and raw-material consumption.

These productivity, process, and people improvements are not easy to accomplish—especially across a network of individual manufacturing sites, each with its own site leadership, IT infrastructure, and workplace culture. It is not uncommon to hear of companies achieving impressive results through pilot programs at one factory site only to find themselves unable to replicate these local wins across their network.

This was the situation at a global industrial company. Facing a considerable ramp-up in demand—volume more than doubled over just three years, which translated to producing more than 50 million additional parts—the business embarked on an ambitious digital transformation at one factory. The goal was to increase overall equipment effectiveness (OEE) by ten percentage points and reduce product unit costs by more than 30 percent.

The project delivered: the factory was admitted to the Global Lighthouse Network , a World Economic Forum initiative, in collaboration with McKinsey, that recognizes leadership in the Fourth Industrial Revolution. The site started welcoming external visitors to showcase its transformation. But despite this achievement, it was unclear to the company how to take this local success story and replicate it across other sites.

Would you like to learn more about our Operations Practice ?

The common pitfalls of scaling digital transformations.

There are five common reasons why manufacturers are not succeeding on this journey.

Siloed implementation. By pursuing digital transformations as a theoretical exercise, many companies unwittingly set up independent delivery teams that are decoupled from business leaders, site operations, manufacturing excellence, and central IT. Others focus too much on replicating a single site experience, failing to appreciate wider network complexities.

Failure to adapt. By deploying a one-size-fits-all approach, manufacturers miss the opportunity to build in the customization and adaptation needed to leverage the unique circumstances, culture, and values of separate factory sites.

Analysis paralysis. Performing a full and deep up-front analysis of an entire network can leave a manufacturer out of steam before a transformation can get off the ground. Instead, robust, accurate-enough insights can be gleaned from a well-developed extrapolation methodology.

Technology-driven rather than value-driven. A technology-first rollout means that solutions are deployed without a clear link to real value opportunities, business challenges, or capability requirements. The result: undermining crucial buy-in from the people charged with making deployment work.

Letting the ‘perfect’ defeat the good. By waiting until a fully fledged, ideal-state data and IT/OT (information technology/operational technology) architecture is defined and implemented before rolling out Industry 4.0 solutions, manufacturers lose out on the shorter time-to-impact made possible through a proven and pragmatic minimal viable architecture.

A technology-first rollout means that solutions are deployed without a clear link to real value opportunities, business challenges, or capability requirements, undermining crucial buy-in from the people charged with making deployment work.

Three company archetypes join the race

Manufacturers playing catch-up to the leading companies generally fall into one of three company archetypes.

The cautious starters. These companies are investigating how to begin their digital-transformation journeys. They need help to identify the full value that Industry 4.0 can bring to their business and to develop a network-wide strategy and deployment road map.

The frustrated experimenters. These companies have started experimenting through pilot programs with some successes. However, they find themselves deploying technologies without a clear understanding of how to achieve financial ROI.

The ready-to-scalers. These companies are deploying solutions and technologies but remain unable to maximize the returns or scale at pace across their networks. They need to recalibrate by focusing on how to capture the full benefits of Industry 4.0 or how to accelerate rollout to respond to shifts in business and customer needs.

Slowing down to go fast

No matter where a company falls on the spectrum of archetypes, there is great value in slowing down and regrouping around a new, more targeted strategy aimed at maximizing the value of a digital transformation.

An important lesson from the few organizations that have succeeded in scaling digital innovations is how they started their impact journey. Before jumping headfirst into procurement and deployment, the leading companies spend time identifying the full potential of Industry 4.0—pinpointing high-leverage areas across the manufacturing value chain—and architecting a laser-focused digital-manufacturing strategy and deployment road map.

The first phase of this approach includes a network scan to identify the value at stake and a priority list of technology use cases, taking into consideration data, IT/OT, and organizational maturity. An accompanying road map can then build on this groundwork, defining the deployment strategy and targeted sites for initial rollout, followed by a network-wide rollout plan to reach scale.

Taking the time up front to perform a network scan to find opportunities for big wins and quick wins can create significant momentum for a digital transformation. As manufacturing sites begin to capture financial and operational value—not to mention the benefits associated with improved organizational capabilities, workforce satisfaction, customer service performance, and environmental impact—these returns can create a virtuous feedback loop where programs become self-funding and initiatives translate more quickly into competitive advantage.

Scaling success

It is this methodology that underpinned the approach taken by the industrial company mentioned earlier. Following its lighthouse success, the business needed to understand how and where to invest to maximize returns across its network. By performing a network scan on a subset of its manufacturing value streams across more than a dozen sites, it identified five sites that together represented around 80 percent of the value at stake. Further, it found that ten out of the 17 identified use cases for technology accounted for 75 percent of the potential impact.

With a sound value-capture deployment strategy in place, and after structurally investing in the required capabilities, the company was able to replicate the network scan approach across the rest of its manufacturing network and scale to other business areas. A senior stakeholder in the company said: “We essentially wrote the playbook for how to scale this into our other sites and are making great progress in these places—not only across our downstream production network but also within our upstream production sites, leveraging digital to reduce human interventions and increase compliance.”

Focus on real business needs and current performance challenges, and follow a “strengths upward” approach, building on solutions that have already worked well at individual sites and can be rolled out pragmatically across the network.

In another example, a global consumer company had been piloting digital innovations in a number of business units for some time, but with few ideas achieving much impact beyond the individual line or site. Company leaders recognized the need to clarify which digital solutions could contribute to overall business needs and priorities, and where to focus transformation efforts to implement solutions at scale.

Following two months of up-front analysis focused on eight prioritized sites from a network of more than 40 factories in Europe and North America, the company realized that about 20 sites accounted for 80 percent of the total savings potential. It also identified a prioritized portfolio of digital solutions, with about two dozen use cases having relevance across the entire network, and a dozen identified as “no regrets” priorities.

Crucially, the process has enabled the company to understand the level of readiness of its data and technology infrastructure and the investment required in technical, managerial, and transformational capabilities. The company came out of the two months with an aligned and value-oriented road map for rolling out a digital transformation across its network. The plan integrated both digital and traditional lean or Six Sigma improvements, accounted for resources and technology requirements, and reflected a clear strategy for building capabilities at scale. The company went on to deploy at scale across multiple sites, pursuing more than $100 million of identified savings.

The seven golden principles for getting the best out of Industry 4.0

Whether manufacturers are starting out on their digital-transformation journeys—or recalibrating their approach after false starts or failed attempts—the approaches adopted by leading companies point to seven golden principles for scaling a successful digital transformation.

Communicate well and often. Establish an effective engagement plan and regular communication with critical senior stakeholders, site leaders, and a cross-functional core team.

Lighthouses reveal a playbook for responsible industry transformation

Be specific. Focus on real business needs and current performance challenges, and follow a “strengths upward” approach, building on solutions that have already worked well at individual sites and can be rolled out pragmatically across the network.

Segment, select, and syndicate. Segment the manufacturing network and select representative sites for an up-front network scan. Syndicate the extrapolation methodology up front to indicate how focused insights will be scaled to derive a networkwide analysis.

Formalize the value at stake. In each assessed site, describe the actual value at stake by linking the most applicable Industry 4.0 solutions or use cases with current digital readiness, data availability, and IT/OT architecture.

Develop a three- to five-year vision for the network. Describe the total value at stake from prioritized bundles of use cases to align business leaders on the ambition, and form a compelling change story for the broader organization. An engaging visual representation of the key solutions can help to engage the broader organization with the vision (Exhibit 2).

Design a digital-manufacturing road map. Develop a prioritized rollout plan with a clear scaling strategy and articulation of the value to capture over time, integrating enablement of data and IT/OT architecture as well as resourcing requirements, capabilities, and change management.

Syndicate the vision and secure leadership buy-in. Circulate the business case and requirements with key stakeholders, aiming for a clear mandate from top leadership and close engagement on target setting and execution from site leaders.

Whether stuck in pilot purgatory or under mounting pressure to demonstrate returns, companies can become dispirited and discouraged. However, by taking just one or two months to slow down and develop a robust manufacturing strategy and deployment road map, companies can accelerate their Industry 4.0 transformations and chart a clear journey forward for the next few years.

Ewelina Gregolinska is an associate partner in McKinsey’s London office, where Rehana Khanam is a partner and Prashanth Parthasarathy is a senior expert; Frédéric Lefort is a partner in the Gothenburg office.

The authors wish to thank Søren Fritzen, Sven Houthuys, Regis Peylet, Mikhail Razhev, and Hariharan Vijaykumar for their contributions to this article.

Explore a career with us

Related articles.

Toward smart production: Machine intelligence in business operations

The mainstreaming of additive manufacturing

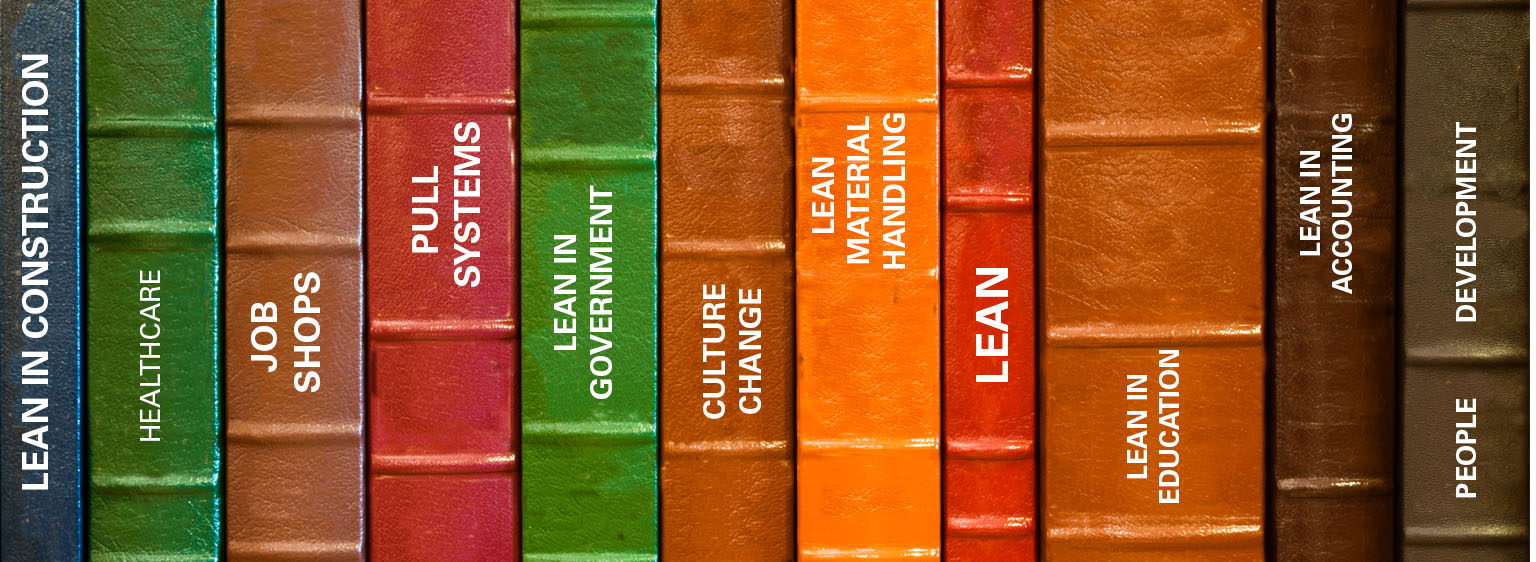

The Lean Post / Articles / Lean Management Case Studies Library

Lean Management Case Studies Library

By Chet Marchwinski

May 16, 2014

Learn how a variety of businesses and organizations used lean management principles to solve real business problems. We’ve arranged the examples in 16 categories to help you find the ones right for your environment.

Lean Management Examples from a Variety of Businesses

The following case studies of lean management principles in action show you how a variety of real businesses solved real business problems under diverse conditions.

We’ve arranged the stories in 16 categories to help you find the examples you need. There is some overlap. For instance, a “Lean Manufacturing” case study may also appear with “Privately Held Companies.”

Lean Manufacturing

- Logistics, Supply Chain, and Warehousing

- Lean Material Handling

- Job Shops (Low-volume, High-mix Manufacturing); Tool and Die

- Lean in Government

- Lean Healthcare

- Lean Accounting

- Lean Construction

- Lean in Office and Service Processes

- Lean in Education

Problem Solving

Pull Systems

Culture Change

People Development

Privately Held Companies

Maintenance

Many of the executives who took part in these transformations are interviewed in LEI’s Senior Executive Series on Lean Leadership . After reading the case studies, be sure to get their personal perspectives on leading change. (Feel free to link to this page, but please respect the copyrights of LEI and journalists by not copying the articles.)

Are you doing something new or notable in the practice of lean management? Let us share what you learned with the lean community. For more information, contact LEI’s Director of Communications Chet Marchwinski at cmarchwinski at lean dot org

Thrustmaster Turns Around

Learn how Thrustmaster of Texas successfully adopted lean thinking and practices to make sustainable improvements in a short period of time, and how other manufacturers of highly engineered, low-volume products can follow their lead using the Lean Transformation Framework.

Lean + Circular Principals = a New True North for Manufacturer

SunPower’s lean journey resembled most others until it defined a new mission, a new True North by combining lean principals with those of the “circular economy” to launch what it is calling a CLean Transformation.

Sustain Your Lean Business System with a “Golden Triangle” After a medical device maker took a hit to margins to fight off global competition, it rebuilt them by lifting its lean operating system to a higher level and keeping it there with a “golden triangle” of sustainability.

Followup Story:

Manufacturing Balancing Act: Pull Versus ERP

In this follow-up to “Sustain Your Lean Business System with a ‘Golden Triangle,’” a case study about Phase 2 Medical Manufacturing, the company needs warehouse space to keep pace with sales growth spurred by the lean transformation. Instead, it expands a pull system by connecting the plan-for-every-part database that underpins one-piece flow production with ERP, typically associated with big batch production.

Cultivating a Lean Problem-Solving Culture at O.C. Tanner If you are in the “appreciation business”, you have to live it in your own workplace. For O.C. Tanner that meant a lean transformation had to show the company appreciated and wanted people’s problem-solving ideas. Here’s a report on that effort, including what worked and what didn’t.

Lean Partnership with Dealer Network Helps Vermeer Reduce End-to-End Inventory on Top Sellers

A lean transformation had taken heavy-equipment manufacturer Vermeer away from batch manufacturing, but batch ordering by dealers was delaying how quickly they got equipment like brush chippers. Learn how it began converting its domestic industrial-line distribution network to lean replenishment, improving service to end customers and improving cash flow for Vermeer and its dealers.

Herman Miller’s Experiment in Excellence At Herman Miller, the lean management effort helps it build problem solvers as well as world-class office furniture. And as this case study shows, lean practices also helped it weather a brutal recession.

Build Your “House” of Production on a Stable Foundation Rigorous problem solving creates basic stability in a machining intensive facility.

A Journey to Value Streams: Reorganizing Into Five Groups Drives Lean Improvements and Customer Responsiveness An approach to creating a value-stream culture centered on autonomy, entrepreneurialism, and lean principles.

Change in Implementation Approach Opens the Door at EMCO to Greater Gains in Less Time A relatively quick, intensive project accelerates the rate of improvement and creates a showcase facility for spreading lean concepts.

Creating the Course and Tools for a Lean Accounting System A lean accounting implementation fills the frustrating disconnect between shop-floor improvements and financial statements.

For Athletic Shoe Company, the Soul of Lean Management Is Problem Solving After taking a lean tools approach to change, management re-organized the transformation around problem solving and process improvement to create a culture that engaged people while boosting performance.

Knife Company Hones Competitiveness by Bucking the Status Quo An iconic family-owned company turns to lean manufacturing to reduce costs by at least 30% to keep its U.S. operations open.

Lean Transformation Lives and Dies with Tools and Dies After a failed first try at just-in-time production , a company transforms tool maintenance, design, and fabrication to create a solid foundation for a second attempt.

Seasoned Lean Effort Avoids “Flavor-of-the-Month” Pitfall A look at how one company’s approach to what new tools it introduced, in what order, and how it prevented each new technique from being viewed as a “flavor of the month” fad.

Shifting to Value-Stream Managers: a Shop-Floor Revolution Leads to a Revolution in Plant Organization

Two years into a lean transformation, the low-hanging fruit has been plucked and progress has started to slow. Read how a Thomas & Betts plant recharged the transformation and reached higher levels of performance by using value-stream managers to span functional walls.

Using Plan-Do-Check-Act as a Strategy and Tactic for Helping Suppliers Improve

At Medtronic’s Neuromodulation business unit, the plan-do-check-act cycle is used on a strategic level to guide overall strategy for selecting and developing key suppliers as well as on a tactical level for guiding lean transformations at supplier facilities.

back to top

Logistics, Supply Chain, and Warehousing How a Retailer’s Distribution Center Exemplifies the Lean Precept “Respect for People,” and Reaps the Benefits

To make sure training engaged and resonated with people after previous attempts at a lean transformation faltered, LifeWay matched lean management tools and principles to its Bible-based culture and language.

Lean management case study series: Lean in Distribution: Go to Where the Action Is!

Starting with daily management walkabouts and standard work , this distributor had laid the groundwork for steady gains for years to come, just two years after its first kaizen workshop .

Putting Lean Principles in the Warehouse

Executives at Menlo Worldwide Logistics saw an opportunity to leapfrog the competition by embracing lean in its outsourced warehousing and receiving operations.

Lean Thinking Therapy Spreads Beyond the Shop

A company expands the lean transformation from the shop floor to international distribution, domestic shipping, and product development.

Sell One, Buy One, Make One: Transforming from Conventional to Lean Distribution

Large inventories to cover fluctuations in demand once characterized Toyota’s service parts distribution system — but no more. Here’s how one DC made the switch.

Material Handling

Following Four Steps to a Lean Material-Handling System Leads to a Leap in Performance

Creating the critical Plan for Every Part was one step in a methodical four-step implementation process to replace a traditional material-handling system.

Low-volume, High-mix Manufacturing; Tool and Die

The Backbone of Lean in the Back Shops

Sikorsky managers apply the lean concept of “every part, every interval” (EPEI) to level the mix in demand and create flow through a key manufacturing cell .

Landscape Forms Cultivates Lean to Fuel Growth Goals

With single-item orders 80% of the time, a low-volume, high-mix manufacturer decided single-piece flow cells were the best way decided the best way to add new products without having to constantly reconfigure production.

Lean Transformation Lives and Dies with Tools and Dies

After a failed first try at just-in-time production, a company transforms tool maintenance, design, and fabrication to create a solid foundation for a second attempt.

Canada Post Puts Its Stamp on a Lean Transformation

The “ inventory ” of mail already is paid for, so moving it faster doesn’t improve cash flow as in lean manufacturing. But Canada Post discovered that traditional batch-and-queue postal operations could benefit from lean principles.

Lean Thinking in Government: The State of Iowa

This story examines a kaizen event at a veterans home and more broadly at the lean effort in Iowa government.

Lean Thinking Helps City of Chula Vista with Budget Crunch

Goodrich Aerostructures’ Chula Vista plant introduces city government to lean thinking and practices so in order to maintain municipal services without resorting to further cuts in the workforce.

Using Lean Thinking to Reinvent City Government

Grand Rapids, MI, turns to lean principles to consolidate operations, eliminate wasted time and effort, and streamline to improve productivity while providing the quality of service that residents want.

Transforming Healthcare: What Matters Most? How the Cleveland Clinic Is Cultivating a Problem-Solving Mindset and Building a Culture of Improvement

The Cleveland Clinic reinvents its continuous improvement program to instill a problem-solving mindset and the skillset to solve everyday problems among the clinic’s thousands of caregivers.

View from the Hospital Floor: How to Build a Culture of Improvement One Unit at a Time

In order to do more and improve faster, the Cleveland Clinic is rolling out a methodology for building a “culture of improvement” across the 48,000-employee hospital system as this followup to the above story shows. Here’s how it works according to the people making the changes.

Dentist Drills Down to the Root Causes of Office Waste

Dentistry is a job shop that Dr. Sami Bahri is out to improve fundamentally for the benefit of patients through the application of lean principles.

Lean management case study series: Pediatric Hospital in Tough Market Pegs Growth to Lean Process Improvement

Lean improvement projects at Akron Children’s Hospital have saved millions of dollars, increased utilization of expensive assets, and reduced wait times for patients and their families.

Lean Design and Construction Project an Extension of Lean Commitment at Akron Children’s Hospital

Input from nurses, doctors, therapists, technicians, and patient parents heavily influenced design decisions..

“Pulling” Lean Through a Hospital

A thoughtful rollout of lean principles in the ER and eye-opening results created a “pull” for lean from other departments.

Best in Healthcare Getting Better with Lean

Mayo Clinic, Rochester, MN, stresses to doctors that the lean effort is aimed not at changing the moment of care, the touch moment between doctor and patient, but the 95% of the time when the patient is not in the doctor’s office

Fighting Cancer with Linear Accelerators and Accelerated Processes

Cross-functional team design and implement a lean process to dramatically increase the number of patients with brain and bone metastases receiving consultation, simulation, and first treatment on the same day without workarounds or expediting.

Massachusetts General Looks to Lean

A proton therapy treatment center, for many adults and children the best hope of beating cancer, applies lean principles to increase capacity.

New Facility, New Flow, and New Levels of Patient Care: The wait is over for patients at the Clearview Cancer Institute in Alabama

Physicians and staff have tirelessly reengineer processes and patient flow to eliminate as much waiting and waste as possible.

The Anatomy of Innovation

At a hospital in Pittsburgh, the emerging vision for the “hospital of the future” is described as giving the right patient, the right care, at the right time, in the right way, all the time.

Creating the Course and Tools for a Lean Accounting System

A lean accounting implementation fills the frustrating disconnect between shop-floor improvements and the financial statement.

Knife Company Hones Competitiveness by Bucking the Status Quo

An iconic family-owned company turns to lean manufacturing to reduce costs by at least 30% to keep its U.S. operations open.

Office and Service Processes

The “inventory” of mail already is paid for, so moving it faster doesn’t improve cash flow as in lean manufacturing. But Canada Post discovered that traditional batch-and-queue postal operations could benefit from lean principles.

Lean Landscapers

At an Atlanta landscaping company, lean practices are making inroads into a service industry in unusual yet fundamental ways.

LSG Sky Chefs Caters to New Market Realities

Business at airline caterer LSG Sky Chefs dropped 30% when airlines cut flights after the terrorist attacks on September 11, 2001. Sky Chefs responded with a rapid launch of a lean initiative.

leveraging Lean to Get the Oil Out

Aera Energy LLC, a California oil and gas company, relies on lean principles to improve key processes, including drilling new wells, repairing existing ones, and maximizing the number of barrels of crude pumped each day.

Columbus Public Schools Use Process Thinking to Improve Academic Achievement.

Columbus, OH, public schools, experiment with lean tools and process thinking to remove wasteful activities that don’t help them help students learn.

Lean Inroads into Alabama Academia

How the University of Alabama in Huntsville integrated lean concepts throughout its industrial engineering curriculum.

Linking Lean Thinking to the Classroom

Value-stream mapping is one of many activities included in the Ford Partnership for Advanced Studies (Ford PAS), an academic program designed to link high-school classroom learning to the skills needed in college and business.

Build Your “House” of Production on a Stable Foundation

Rigorous problem solving creates basic stability in a machining intensive facility.

For Athletic Shoe Company, the Soul of Lean Management Is Problem Solving

After talking a lean tools approach to change, management re-organized the transformation around problem solving and process improvement to create a culture that engaged people while boosting performance.

Toothbrush Plant Reverses Decay in Competitiveness

The rapid introduction of a lean system, beginning with just-in-time production and pull, helps a highly automated Midwest plant fight off overseas competition by reducing lead times and inventory while augmenting the plant’s advantage in service.

A Journey to Value Streams: Reorganizing Into Five Groups Drives Lean Improvements and Customer Responsiveness

An approach to creating a value-stream culture centered on autonomy, entrepreneurialism, and lean principles.

Making Lean Leaders — Ariens internship program develops lean and leadership skills

Besides making snow-blowers, mowers, and string trimmers, Ariens Co., of Brillion, WI, makes lean leaders.

Starting with daily management walkabouts and standard work, this 84-year-old, family-owned distributor laid the groundwork for steady gains for years to come, just two years after its first kaizen workshop.

Sustain Your Lean Business System with a “Golden Triangle”

After a medical device maker took a hit to margins to fight off global competition, it rebuilt them by lifting its lean operating system to a higher level and keeping it there with a “golden triangle” of sustainability. You’ll recognize two elements of the triangle right away: visual control and standardized work . The third, accountability management or a kamishibai system, is probably less well known but just as critical.

Cultivating a Lean Problem-Solving Culture at O.C. Tanner

If you are in the “appreciation business”, you have to live it in your own workplace. For O.C. Tanner that meant a lean transformation had to show the company appreciated and wanted people’s problem-solving ideas. Here’s a report on that effort, including what worked and what didn’t.

Lean Thinking in Aircraft Repair and Maintenance Takes Wing at FedEx Express

A major check that used to take 32,715 man-hours was cut to 21,535 hours in six months. That translated into a $2 million savings, which dovetailed with the company’s emphasis on reducing costs during the recession.

Construction

Input from nurses, doctors, therapists, technicians, and patient parents heavily influenced design decisions—from incorporating emergency room hallways that protect the privacy of abused children to the number of electrical outlets in each neonatal intensive care room.

Virtual Lean Learning Experience (VLX)

A continuing education service offering the latest in lean leadership and management.

Written by:

About Chet Marchwinski

Chet has been a humble, unwashed scribe of the lean continuous improvement movement since books by Taiichi Ohno and Shigeo Shingo first hit North America in the 1980s. At LEI, he contributes to content creation, marketing, public relations, and social media. Previously, he also wrote case studies on lean management implementations in…

Leave a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Be the first to learn of new learning opportunities and the latest practical, actionable information. Subscribe to an LEI newsletter.

Join us on social, privacy overview.

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

HBS Case Selections

NIO: A Chinese EV Company's Global Strategy

- William C. Kirby

- Noah B. Truwit

India: Will the Giant Emerge?

- Christian H.M. Ketels

- Radhika Kak

JPMorgan Chase in Paris

- Joseph L. Bower

- Dante Roscini

- Elena Corsi

- Michael Norris

OpenAI: Idealism Meets Capitalism

- Shikhar Ghosh

- Shweta Bagai

Generative AI and the Future of Work

- Christopher Stanton

- Matt Higgins

Copilot(s): Generative AI at Microsoft and GitHub

- Frank Nagle

- Shane Greenstein

- Maria P. Roche

- Nataliya Langburd Wright

- Sarah Mehta

Innovation at Moog Inc.

- Brian J. Hall

- Ashley V. Whillans

- Davis Heniford

- Dominika Randle

- Caroline Witten

Innovation at Google Ads: The Sales Acceleration and Innovation Labs (SAIL) (A)

- Linda A. Hill

- Emily Tedards

Juan Valdez: Innovation in Caffeination

- Michael I. Norton

- Jeremy Dann

UGG Steps into the Metaverse

- Shunyuan Zhang

- Sharon Joseph

- Sunil Gupta

- Julia Kelley

Metaverse Wars

- David B. Yoffie

Roblox: Virtual Commerce in the Metaverse

- Ayelet Israeli

- Nicole Tempest Keller

Timnit Gebru: "SILENCED No More" on AI Bias and The Harms of Large Language Models

- Tsedal Neeley

- Stefani Ruper

Hugging Face: Serving AI on a Platform

- Kerry Herman

- Sarah Gulick

SmartOne: Building an AI Data Business

- Karim R. Lakhani

- Pippa Tubman Armerding

- Gamze Yucaoglu

- Fares Khrais

Honeywell and the Great Recession (A)

- Sandra J. Sucher

- Susan Winterberg

Target: Responding to the Recession

- Ranjay Gulati

- Catherine Ross

- Richard S. Ruback

- Royce Yudkoff

Hometown Foods: Changing Price Amid Inflation

- Julian De Freitas

- Jeremy Yang

- Das Narayandas

Elon Musk's Big Bets

- Eric Baldwin

Elon Musk: Balancing Purpose and Risk

Tesla's ceo compensation plan.

- Krishna G. Palepu

- John R. Wells

- Gabriel Ellsworth

China Rapid Finance: The Collapse of China's P2P Lending Industry

- Bonnie Yining Cao

- John P. McHugh

Forbidden City: Launching a Craft Beer in China

- Christopher A. Bartlett

- Carole Carlson

Booking.com

- Stefan Thomke

- Daniela Beyersdorfer

Innovation at Uber: The Launch of Express POOL

- Chiara Farronato

- Alan MacCormack

Racial Discrimination on Airbnb (A)

- Michael Luca

- Scott Stern

- Hyunjin Kim

Unilever's Response to the Future of Work

- William R. Kerr

- Emilie Billaud

- Mette Fuglsang Hjortshoej

AT&T, Retraining, and the Workforce of Tomorrow

- Joseph B. Fuller

- Carl Kreitzberg

Leading Change in Talent at L'Oreal

- Lakshmi Ramarajan

- Vincent Dessain

- Emer Moloney

- William W. George

- Andrew N. McLean

Eve Hall: The African American Investment Fund in Milwaukee

- Steven S. Rogers

- Alterrell Mills

United Housing - Otis Gates

- Mercer Cook

The Home Depot: Leadership in Crisis Management

- Herman B. Leonard

- Marc J. Epstein

- Melissa Tritter

The Great East Japan Earthquake (B): Fast Retailing Group's Response

- Hirotaka Takeuchi

- Kenichi Nonomura

- Dena Neuenschwander

- Meghan Ricci

- Kate Schoch

- Sergey Vartanov

Insurer of Last Resort?: The Federal Financial Response to September 11

- David A. Moss

- Sarah Brennan

Under Armour

- Rory McDonald

- Clayton M. Christensen

- Daniel West

- Jonathan E. Palmer

- Tonia Junker

Hunley, Inc.: Casting for Growth

- John A. Quelch

- James T. Kindley

Bitfury: Blockchain for Government

- Mitchell B. Weiss

Deutsche Bank: Pursuing Blockchain Opportunities (A)

- Lynda M. Applegate

- Christoph Muller-Bloch

Maersk: Betting on Blockchain

- Scott Johnson

Yum! Brands

- Jordan Siegel

- Christopher Poliquin

Bharti Airtel in Africa

- Tanya Bijlani

Li & Fung 2012

- F. Warren McFarlan

- Michael Shih-ta Chen

- Keith Chi-ho Wong

Sony and the JK Wedding Dance

- John Deighton

- Leora Kornfeld

United Breaks Guitars

David dao on united airlines.

- Benjamin Edelman

- Jenny Sanford

Marketing Reading: Digital Marketing

- Joseph Davin

Social Strategy at Nike

- Mikolaj Jan Piskorski

- Ryan Johnson

The Tate's Digital Transformation

Social strategy at american express, mellon financial and the bank of new york.

- Carliss Y. Baldwin

- Ryan D. Taliaferro

The Walt Disney Company and Pixar, Inc.: To Acquire or Not to Acquire?

- Juan Alcacer

- David J. Collis

Dow's Bid for Rohm and Haas

- Benjamin C. Esty

Finance Reading: The Mergers and Acquisitions Process

- John Coates

Apple: Privacy vs. Safety? (A)

- Henry W. McGee

- Nien-he Hsieh

- Sarah McAra

Sidewalk Labs: Privacy in a City Built from the Internet Up

- Leslie K. John

Data Breach at Equifax

- Suraj Srinivasan

- Quinn Pitcher

- Jonah S. Goldberg

Apple's Core

- Noam Wasserman

Design Thinking and Innovation at Apple

- Barbara Feinberg

Apple Inc. in 2012

- Penelope Rossano

Iz-Lynn Chan at Far East Organization (Abridged)

- Anthony J. Mayo

- Dana M. Teppert

Barbara Norris: Leading Change in the General Surgery Unit

- Boris Groysberg

- Nitin Nohria

- Deborah Bell

Adobe Systems: Working Towards a "Suite" Release (A)

- David A. Thomas

- Lauren Barley

Home Nursing of North Carolina

Castronics, llc, gemini investors, angie's list: ratings pioneer turns 20.

- Robert J. Dolan

Basecamp: Pricing

- Frank V. Cespedes

- Robb Fitzsimmons

J.C. Penney's "Fair and Square" Pricing Strategy

J.c. penney's 'fair and square' strategy (c): back to the future.

- Jose B. Alvarez

Osaro: Picking the best path

- James Palano

- Bastiane Huang

HubSpot and Motion AI: Chatbot-Enabled CRM

- Thomas Steenburgh

GROW: Using Artificial Intelligence to Screen Human Intelligence

- Ethan S. Bernstein

- Paul D. McKinnon

- Paul Yarabe

GitLab and the Future of All-Remote Work (A)

- Prithwiraj Choudhury

- Emma Salomon

TCS: From Physical Offices to Borderless Work

Creating a virtual internship at goldman sachs.

- Iavor Bojinov

- Jan W. Rivkin

Starbucks Coffee Company: Transformation and Renewal

- Nancy F. Koehn

- Kelly McNamara

- Nora N. Khan

- Elizabeth Legris

JCPenney: Back in Business

- K. Shelette Stewart

- Christine Snively

Arup: Building the Water Cube

- Robert G. Eccles

- Amy C. Edmondson

- Dilyana Karadzhova

(Re)Building a Global Team: Tariq Khan at Tek

Managing a global team: greg james at sun microsystems, inc. (a).

- Thomas J. DeLong

Organizational Behavior Reading: Leading Global Teams

Ron ventura at mitchell memorial hospital.

- Heide Abelli

Anthony Starks at InSiL Therapeutics (A)

- Gary P. Pisano

- Vicki L. Sato

Wolfgang Keller at Konigsbrau-TAK (A)

- John J. Gabarro

The 2010 Chilean Mining Rescue (A)

- Faaiza Rashid

IDEO: Human-Centered Service Design

- Ryan W. Buell

- Andrew Otazo

- Benjamin Jones

- Alexis Brownell

Midland Energy Resources, Inc.: Cost of Capital

- Timothy A. Luehrman

- Joel L. Heilprin

Globalizing the Cost of Capital and Capital Budgeting at AES

- Mihir A. Desai

- Doug Schillinger

Cost of Capital at Ameritrade

- Mark Mitchell

- Erik Stafford

Finance Reading: Cost of Capital

Circles: series d financing.

- Paul W. Marshall

- Kristin J. Lieb

- William A. Sahlman

- Michael J. Roberts

Andreessen Horowitz

- Thomas R. Eisenmann

Entrepreneurship Reading: Partnering with Venture Capitalists

- Jeffrey J. Bussgang

David Neeleman: Flight Path of a Servant Leader (A)

- Matthew D. Breitfelder

Coach Hurley at St. Anthony High School

- Scott A. Snook

- Bradley C. Lawrence

Shapiro Global

- Michael Brookshire

- Monica Haugen

- Michelle Kravetz

- Sarah Sommer

Kathryn McNeil (A)

- Joseph L. Badaracco Jr.

- Jerry Useem

Carol Fishman Cohen: Professional Career Reentry (A)

- Myra M. Hart

- Robin J. Ely

- Susan Wojewoda

Alex Montana at ESH Manufacturing Co.

- Michael Kernish

Michelle Levene (A)

- Tiziana Casciaro

- Victoria W. Winston

John and Andrea Rice: Entrepreneurship and Life

- Howard H. Stevenson

- Janet Kraus

- Shirley M. Spence

Partner Center

Lean Six Sigma for the improvement of company processes: the Schnell S.p.A. case study

The TQM Journal

ISSN : 1754-2731

Article publication date: 15 October 2021

Issue publication date: 17 December 2021

The aim of this study is to develop an in-depth case study on the implementation on Lean six sigma (LSS) in Schnell S.p.A., Italian company leader of an important multinational industrial group, highlighting the benefits that can be achieved from a careful application of this method, the main challenges and organizational learning from its implementation.

Design/methodology/approach

The study has been developed with a qualitative approach, creating a single in-depth case study, with the participant observation of researchers in the project which lasted 4 months. Periodic weekly meetings were done with the working group to exchange feedback on the development of the project to share opinions and data.

A project has been developed to stabilize the procurement process of a pull-type production cell, which experienced delays in supply lead times. The causes of the problems in their process of managing the supply of the production cell were found and some inefficiencies in the internal process of fulfillment of supply orders have been intercepted, the optimization of which has allowed the generation of an automatic system for sending supply orders, coming directly from the production line.

Originality/value

This study described the path and dynamics of the transformation process that business organizations undertake for optimizing their profitability and competitive advantage, placing emphasis on an innovative methodology for conducting business process improvement projects, which constitutes its operating philosophy on the effective and efficient use of company resources and skills, to guarantee to the company the achievement of a lasting and defensible competitive advantage over time.

- Lean thinking

- Lean production

- Quality management

- Continuous improvement

Murmura, F. , Bravi, L. , Musso, F. and Mosciszko, A. (2021), "Lean Six Sigma for the improvement of company processes: the Schnell S.p.A. case study", The TQM Journal , Vol. 33 No. 7, pp. 351-376. https://doi.org/10.1108/TQM-06-2021-0196

Emerald Publishing Limited

Copyright © 2021, Federica Murmura, Laura Bravi, Fabio Musso and Aleksandra Mosciszko

Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

1. Introduction

The development of an effective quality improvement or continuous improvement strategy is a key factor for long-term success of modern organizations. Over the last decade, Lean Six Sigma (LSS) has become one of the most popular and proven business process improvement methodologies organizations have ever witnessed in the past ( Antony et al. , 2017 ), and it has been accepted globally as a management strategy for achieving Process Excellence ( Gijo et al. , 2019 ).

Lean Six Sigma is a management strategy for improving corporate productivity and profitability, that aim to maximize the Customer satisfaction by reducing constraints which the company organization is subject in terms of activities that do not create value for the Customer. In practice, LSS is an improvement strategy that analyze quantitative data on business performance to identify, eliminate and control problems and inefficiencies related to manufacturing cost, service cost, quality, productivity and customer satisfaction ( Singh and Rathi, 2019 ; Snee, 2010 ) throughout the business processes.